Model: K-Series

Installation Instructions

8

DISPLAY INSTALLATION

SINGLE DISPLAY AND KCY-210/-220

NOTE:

If you are installing DUAL / TRIPLE displays

(Except KCY-210/-220), then proceed to page 9.

The mounting holes on the back of your display will either

be

flush with

the back surface, or

recessed into

the back

surface. Refer to the applicable installation procedure.

FLUSH MOUNTING HOLES

1.

Verify that you have the following parts:

CAUTION:

Using screws of improper size may

damage your display! Proper screws will easily and

completely thread into display mounting holes.

CAUTION:

Inadequate thread engagement in display

may cause display to fall! Back out screws ONLY as

necessary to allow installation of Centris bracket!

2.

Ensure Centris bracket is able to swivel and tilt easily,

yet still be tight enough to hold display in desired

position. Adjust as required before proceeding. See

"ADJUSTMENT" for detail.

3.

Using Phillips screwdriver, carefully install two screws

(20) into the

upper

mounting holes on the display.

Thread screws completely into display, then back out

3 complete turns.

4.

Pick up and align display so that screws (20) (installed

on the back of the display in the previous step) fit into

the mounting holes on the Centris bracket; rotate the

bracket as required (See Figure 11). Lower the

display firmly into place.

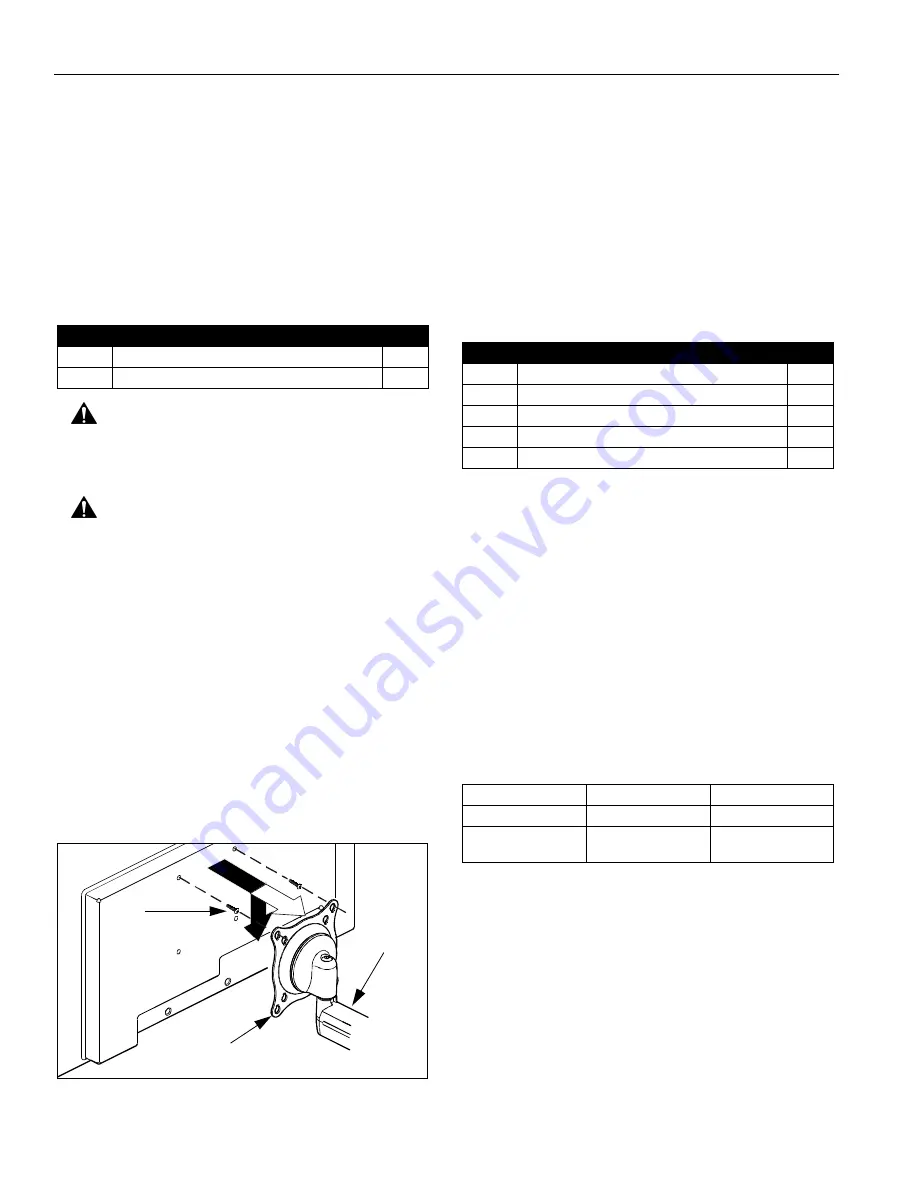

Figure 11: Single Display - Flush Mount

5.

Using Phillips screwdriver, install two remaining

screws (20) through the

lower

mounting holes in

Centris bracket into the display.

6.

Tighten all four screws (20). Do not overtighten!

7.

KCY-210/-220 Only: Repeat Steps 1-6 for second

display.

8.

Proceed to "CABLE MANAGEMENT."

RECESSED MOUNTING HOLES

1.

Verify that you have the following parts:

2.

Ensure Centris bracket is able to swivel and tilt easily,

yet still be tight enough to hold display in desired

position. Adjust as required before proceeding. See

"ADJUSTMENT" for detail.

3.

Carefully place display face down on protective

surface.

4.

Determine depth of recessed mounting holes relative

to back surface of display (against which Centris head

will contact).

5.

Select proper length spacer and screw from table

below:

NOTE:

All spacers used should be the same length. If

the recess depths result in multiple spacer

lengths, then select the longer spacer.

6.

Place the four selected spacers over each of the

mount holes on the back of the display.

7.

Pick up and orient the mount (10) so that the

mounting holes in the Centris bracket are aligned with

the holes in the spacers; rotate the bracket as

required (See Figure 12).

Item

Description

Qty

10

MOUNT, K-Series

1

20

SCREW, Phillips Pan Machine, M4 x 12mm

4

10

20

(2 places)

Centris Bracket

Item

Description

Qty

10

MOUNT, K-Series

1

20

SCREW, Phillips Pan Machine, M4 x 20mm

4

30

SCREW, Phillips Pan Machine, M4 x 30mm

4

40

SPACER, Nylon, 3/8" long

4

50

SPACER, Nylon, 3/4" long

4

IF recess DEPTH is: THEN use spacer:

AND screw:

3/8" or less

40 (3/8" long)

20 (M4 x 20mm)

More than 3/8" up to

and including 3/4"

50 (3/4" long)

30 (M4 x 30mm)