Part no

Issue no

Series no

Date

Page

8940173703

01

C

09/2015

8/12

CP3850

SERVICE

MANUAL

Shaft unit

Di smantling the shaft unit

1. Remove the safety screw using the provided allen key and

locking the output shaft with the stop finger

2. Unscrew the front flange using the provided pin spanner and

locking the output shaft with the stop finger, then remove the

grinding wheel

3. Tighten the front flange of 2 turns on the shaft and remove the

autobalancer taking the tool in the hand slam and taping with a

mallet on the end of the shaft and on the front flange

4. Clamp the head/housing of the tool in a vice. Ensure the stop

finger is not clamped

5. Unscrew the 3 screws CHc M5x12 and remove the washers and

the guard

6. Unscrew the ring screw (R/H thread)

7. Remove the tool from the vice

8. Using a mallet, tap on the housing to slide out the shaft unit

9. Unscrew the nut (R/H thread)

10. Using an extractor, remove the bevel gear and the deflector

11. Using an extractor, remove the bearing

Reassembling the shaft unit

1. Position the new bearing onto the spindle and press it into

position

2. Press the parallel key

3. Place the deflector onto the new bevel gear

4. Position the bevel gear onto the output shaft

5. Apply a drop of LOCTITE 243 on the first thread of the shaft and

tighten the nut (R/H thread 25 Nm)

6. Apply the recommended quantity of grease, réf. 6159901480 (19

ml), onto the shaft bevel gear

7. Clamp horizontally the head/housing of the tool in a vice. Ensure

the stop finger is not clamped

8. Slide the output shaft into the housing and fit it into the needle

bearing taping carefully with a mallet. Check the output for free

rotation

9. Apply a drop of LOCTITE 243 on the first ring screw thread (R/H

thread 45 Nm)

10. Place the guard onto the housing and tighten the 3 screws CHc

M5x12 (R/H thread 5 Nm) with there washer

11. Place the autobalancer on the output shaft

12. Place a new grinding wheel and screw on the front flange with

the provided pin spanner

13. Tighten the safety screw with the provided Allen key

14. Test the tool to make sure it works properly

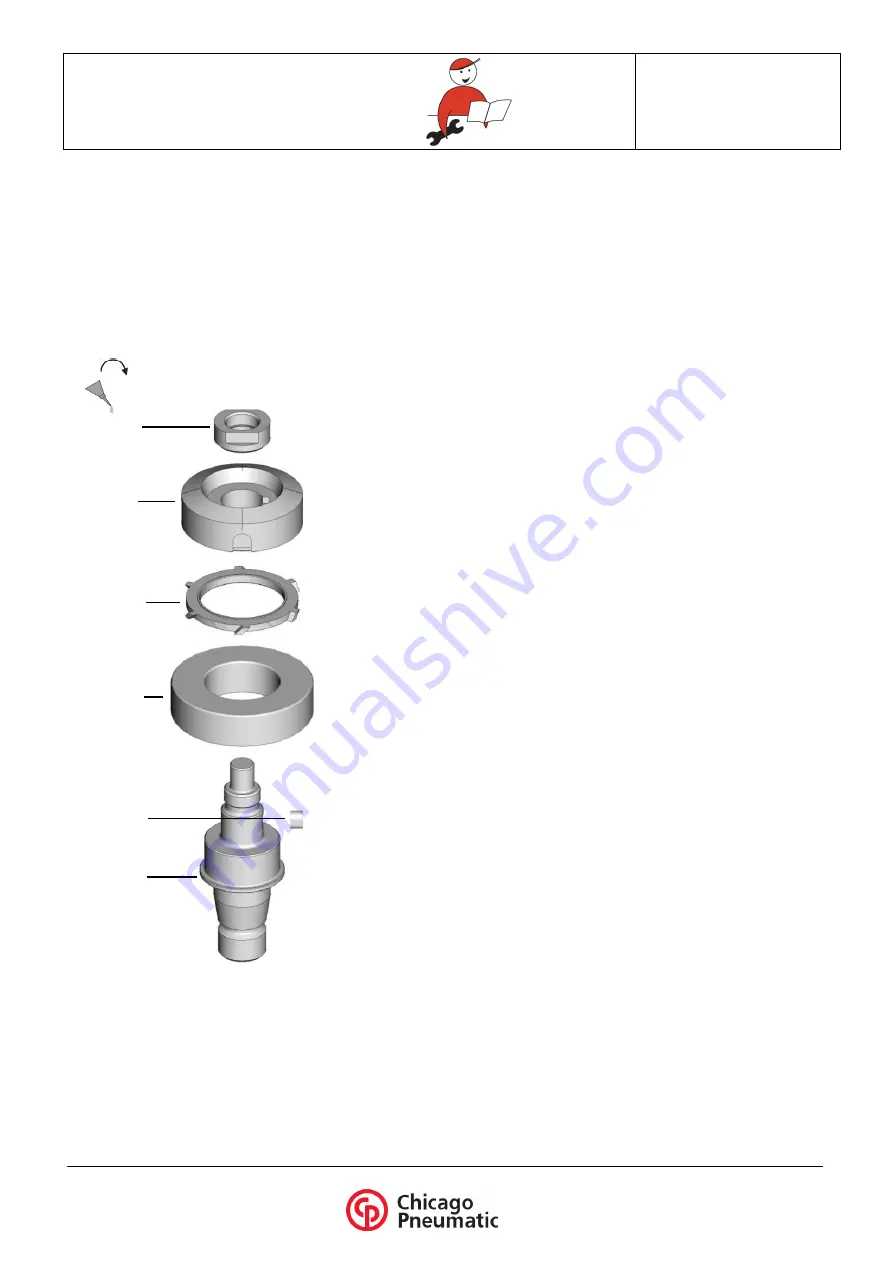

Bearing

Nut

Bevel gear

Déflector

Output spindle

Parallel key

25 Nm

LOCTITE 243