ENGINE-ELECTRICAL 6Y-23

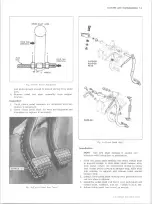

Fig. 14i — L—6 Spark Plug Wire Installation

gages will not give a correct measurement if the elec

trodes are worn. Adjust gap by bending the side elec

trodes only; bending the center electrode will crack the

insulator. Adjust gaps to specification. Setting spark plug

gap to other than specification to effect changes in engine

performance is not recommeded.

CAUTION:

Before adjusting gap, file center elec

trode flat. In adjusting the spark plug gap, never

bend the center electrode which extends through

the porcelain center. Always make adjustment by

bending the ground or side electrode.

Installation of Spark Plugs

When installing spark plugs, make sure that all surfaces

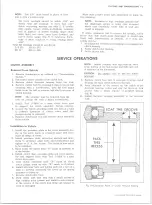

Fig. 15i —V —8 Spark Plug Wire Installation

on plugs and in cylinder heads are clean. When installing

the 5/8” hex tapered seat spark plugs, tighten to 15 lb. ft.,

using a 5/8,; deep socket, an extension and a torque

wrench.

CAUTION:

If tapered seat spark plugs are over-

tightened, they will be more difficult to remove

at the next tune-up.

Installation of Spark Plug Wires

No. 1 spark plug wire is installed in the first distributor

cap tower after the adjusting window, moving in the direc

tion of rotation (V-8), or in the foremost tower (L-6). The

other wires are then installed in a clockwise direction

according to the firing order (figs. 14i and 15i).

STARTING SYSTEM

INDEX

Page

Page

Starting M o to r and Solenoid C h e c k s ........................................6Y-25

C om ponent P a r t R e p lac e m e n t .................................. * ..................6Y-25

GENERAL DESCRIPTION

The function of the starting system, composed of the

starting motor, solenoid and battery, is to crank the

engine. The battery supplies the electrical energy, the

solenoid completes the circuit to the starting motor, and

the motor then does the actual work of cranking the engine.

The starting motor (fig. Is) consists primarily of the

drive mechanism, frame, armature, brushes, and field

windings. The starting motor is a 12-volt extruded frame

type, having four pole shoes and four fields, connected

with the armature. The aluminum drive end housing is

extended to enclose the entire shift lever and plunger

mechanism, protecting them from dirt, splash, and icing.

The flange mounted solenoid switch operates the overrun

ning clutch drive by means of a linkage to the shift lever.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......