CLUTCHES AND TRANSMISSIONS 7-13

ALUMINUM POWERGLIDE

INDEX

General D escription................................................................................ ..... 7-13

Maintenance and A djustm ents................................................................... 7-13

O il Level Check ........................................................................................ 7-13

Periodic O il Change ................................................................................. 7-13

Periodic Low Band A d ju s tm e n t....................................................... ..... 7-14

Manual Shift Linkage Check and A d j u s t .......................................... 7-14

Throttle Valve L in k a g e .................................................................. ......7-15

Neutral Safety S w itc h .......................................................................... 7-15

Throttle Return Check Valve (Dashpot) .......................................... 7-15

Transmission Replacem ent................................................................ ..... 7-16

Page

Warming Up Transmission . . . ..............................................................

Shop Warm U p .....................................................................................

Road Warm U p ................................................................ ....................

Checking Fluid Level and C o n d itio n ..................................................

Basic Pressure Checks ............................................................................

Wide Open Throttle Upshift Pressure C h e ck..................................

Idle Pressure in Drive R a n g e ...................... .......................................

Manual “ Low ” Range Pressure Check .....................................

Drive Range Overrun (Coast) Pressure ............................................

Powerglide Shift P o in ts .........................................................................

GENERAL DESCRIPTION

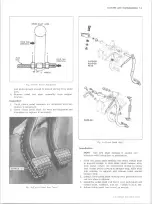

The case and converter housing of the two speed alumi

num Powerglide Transmission is a single case aluminum

unit. When the manual control is placed in the drive po

sition, the transmission automatically shifts to low gear

for initial vehicle movement. As the truck gains speed

and depending on load and throttle position, an automatic

shift is made to high gear. A forced downshift feature

provides a passing gear by returning the transmission to

low range.

The oil pump assembly is a conventional gear type and

the oil pump housing is of the large diameter type acting

as the front bulkhead of the transmission. The torque

converter is a conventional three element welded design

bolted to the engine flywheel which drives through a two-

speed planetary gearset. The high clutch assembly is

typical of the designs used in this type transmission. The

aluminum Powerglide uses an output shaft mounted gov

ernor which requires a hole through the output shaft.

The reverse clutch assembly is a multiple disc type

clutch. The steel plates are splined directly to the case

while the face plates are splined to the internal or ring

gear. The clutch piston operates within the rear portion

of the case. The internal diameter of the piston is sealed

to an integral hub portion of the case rear bulkhead. The

outside diameter is sealed to a machined portion of the

case. The piston is hydraulically applied and is released

by separate coil springs. The valve body assembly is

bolted to the bottom of the transmission case and is ac

cessible for service by removing the oil pan assembly.

The valve body consists of an upper and lower body lo

cated on either side of a transfer plate. The vacuum

modulator is located on the left rear face of the trans

mission case. The modulator valve bore is located in the

upper valve body.

M AINTENANCE A N D ADJUSTMENTS

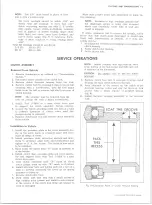

OIL LEVEL CHECK

The transmission oil level should be checked periodi

cally as recommended in Section 0. Oil should be added

only when level is on or below the “ ADD” mark on the

dip stick with oil hot or at operating temperature. The oil

level dip stick is located at the right rear of the engine

compartment. Fill with oil specified in Section 0.

In order to check oil level accurately, the engine should

be idled with the transmission oil hot and the control

lever in neutral (N) position.

It is important that the level be maintained no higher

than the “ FULL” mark on the transmission oil level

gauge. DO NOT OVERFILL, for when the oil level is

at the full mark on the dip stick, it is just slightly be

low the planetary gear unit. If additional oil is added,

bringing the oil level above the full mark, the planetary

unit will run in the oil, foaming and aerating the oil. This

aerated oil carried through the various oil pressure pas

sages (low servo, reverse servo, clutch apply, converter,

etc.) may cause malfunction of the transmission assem

bly, resulting in cavitation noise in the converter and

improper band or clutch application. Overheating may

also occur.

If the transmission is found consistently low on oil, a

thorough inspection should be made to find and correct all

external oil leaks.

PERIODIC OIL CH ANG E

The transmission oil should be changed periodically as

recommended in Section 0, and whenever transmission is

to be removed from the vehicle for repairs.

1. Run engine for one minute in neutral prior to

changing.

2. Be sure vehicle is level or raise from the rear only.

3. Remove the oil pan drain plug and allow oil to drain

thoroughly into a pan or can.

4. Replace drain plug and refill with approximately two

quarts of oil specified in Section 0.

NOTE:

To refill the transmission, remove dip

stick from oil filler tube and refill transmission

with oil specified in Section 0. Then, a f t e r

shifting into all ranges at idle speed to fill all

oil passages, the engine should be run at 800-

1000 rpm with the transmission in Neutral until

the oil warms up, then add oil as required to

raise the fluid level to the full mark on the dip

stick. Refill capacity is approximately 2 qts.

(U.S. measure 1-3/4 qts. Imperial measure).

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......