BRAKES

SECTION 5

INDEX

Page

G e n e ra l D e s c r i p t i o n .................. ...

. ...............................

D isc B rake s - F r o n t .......................................................... ...

D r u m B ra k e s - R e a r ................................................. .....................

M ainte nance and A d ju s t m e n t .............................................................

H y d ra u lic B rake F l u i d ....................................................................

B leeding H y d rau lic S y s t e m ....................................................... ...

P re s s u re B l e e d i n g ..................................... ...........................

M anu al B le e d in g ............................................................................

H y d ra u lic B ra k e L in e s and T u b i n g ........................................ ...

Com ponent R e p la c e m e n t and R e p a i r ..............................................

Page

B rake D r u m R e f in is h in g ............................................................. 5-15

M ain C y lin d e r .................................................

................................. 5-16

B rake P e d a l .........................................................................................5-20

P a rk in g B rake P e d a l ...................................................................... 5-22

P a rk in g B rake A d ju s tm e n t............................................................. 5-22

B rake C o m b in atio n V alve ............................... .. ............................. 5-25

R e a r B ra ke s - U sed W ith R .P .O . H - 2 2 .....................................5-26

P o w e r B ra k e s ........................................................................................ 5-29

Special T o o l s ............................................................................ ........... 5-30

GENERAL DESCRIPTION

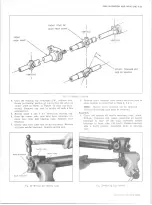

M A IN CYLINDER

(Figs. 1 and 2)

All 10 through 30 series models are equipped with a

dual hydraulic brake system. If a brake line or wheel

cylinder should fail the operator can still bring the ve

hicle to a controlled stop. The system is designed with a

separate hydraulic system for the front and rear brakes

using a dual cylinder. The cylinder has two separate

reservoirs and outlets in a common body casting. On 10

series vehicles the front reservoir controls the front

brake system and the rear reservoir controls the rear

system. On 20-30 series vehicles the front reservoir

controls the rear brake system and the rear reservoir

controls the front system (except on CA 30 with vacuum

over hydraulic boosters where the front is controlled by

the front booster and rear by the rear booster).

All models (except models with vacuum over hydraulic

boosters) have a combination valve located below the main

cylinder. The front and rear hydraulic lines are routed

through this combination “ metering" and "brake failure

warning switch'' to their appropriate wheel cylinders

or caliper.

The metering portion of the combination valve tends to

"hold off” front hydraulic pressure until the rear brake

system overcomes their pull back springs; then pressure

is allowed to flow with the result being a good distribution

of braking effort.

The brake failure warning switch portion of the com

bination valve "senses” a loss of hydraulic pressure, if

a failure should occur and turns "on” a red light in the

dash to warn the operator of the failure.

NOTE:

Vehicles with vacuum over hydraulic

boosters have a warning switch connected to the

brake pedal. This switch "senses pedal travel”

and not hydraulic pressure.

DISC BRAKES FRONT

(Fig. 3)

All models have disc brakes on the front. The one piece

caliper mounts on the steering knuckle/steering arm,

which is also a one piece casting, and astride the brake

disc. The caliper is the single piston design which is said

to be a sliding caliper sliding piston. No front brake

adjustment is necessary once the system is in operation

and the pedal has been stroked to "seat” the shoes to the

caliper.

DRUM BRAKES REAR

(Fig. 4)

The rear brakes are duo servo (except R.P.O. H-22)

which are self adjusting. Brake adjustment takes place

when the brakes are applied with a firm pedal effort while

the vehicle is backing up. Applying the brakes moves the

actuator which turns the star wheel and lengthens the

adjuster screw assembly. This action moves the shoes

outward until clearance between the lining and drum is

within proper limits.

M AIN TENANCE A N D ADJUSTMENTS

HYDRAULIC BRAKE FLUID

Use GM Hydraulic Brake Fluid, Supreme No. 11 or

equivalent when servicing brakes. This brake fluid is

satisfactory for any climate and has all the qualities

necessary for proper operation, such as a high boiling

point to prevent vapor lock and the ability to remain

fluid at low temperatures.

In the event that improper fluid has entered the system,

it will be necessary to service the system as follows:

1. Drain the entire system.

2. Thoroughly flush the system with brake fluid.

NOTE:

Use only brake fluid when flushing a

system.

3. Replace all rubber parts of the system, including

brake hoses.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......