BRAKES 5-2

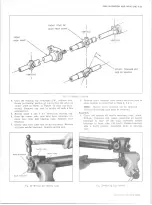

TO FRAME

BOOSTER

TO FRAME

BOOSTER

C- 30 WITH H -22 OPTION

P-30 WITH H-22 OPTION

C-K-P-20-30

Fig. 1— M ain Cylinder - Typical

4, Refill the system.

5. Bleed the system.

BLEEDING HYDRAULIC SYSTEM

The hydraulic brake system must be bled whenever,

any line has been disconnected or air has in some way

entered the system. A "spongy" pedal feeling when the

brakes are applied may indicate presence of air in the

system. The system must be absolutely free of air at all

times. Bleeding of brake system may be performed by

one of two methods - either pressure or manual.

PRESSURE BLEEDING (Figs. 5 an d 6)

NOTE:

Pressure bleeding equipment must be of

the diaphragm type. That is, it must have a rub

ber diaphragm between the air supply and the

brake fluid to prevent air, moisture, oil and

other contaminates from entering the hydraulic

system.

1. Clean all dirt from top of main cylinder and remove

cylinder cover and rubber diaphragm.

2. Reduce fluid level in main cylinder until reservoirs

are approximately half full.

NOTE:

Make sure brake fluid in bleeder equip

ment is at operating level and that the equipment

is capable of exerting 20 to 30 lbs. hydraulic

pressure on the brake system.

3. Install brake bleeder adapter J-23518 (J-23339 for

frame mounted boosters) on main cylinder. Connect

hose from bleeder equipment to bleeder adapter and

open release valve on bleeder equipment.

NOTE:

The combination valve, located near the

main cylinder, must have the plunger depressed

while bleeding - use tool J-23709 as shown in

Figure 5.

4. Install brake bleeder wrench, Tool J-21472 on bleeder

valve at wheel cylinder and install one end of bleeder

hose on bleeder valve.

5. Pour a sufficient amount of brake fluid into a trans

parent container to ensure that end of bleeder hose

will remain sumerged during bleeding. Place the

loose end of bleeder hose into the container. Be sure

the hose end is submerged in the fluid.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......