15

Value) + Last Integral Output value. The minimum and maximum Integral

output is determined by the settings under Integral Windup Protection.

This setting is generally not useful to SCM PID control and should be left

for zero. Customers not experienced with PID tuning are highly

recommended to leave Derivative at 0.000 as it is rarely needed and is

more apt to cause difficulties in tuning the PID. The derivative

component causes the output to change in response to changes in the

process variable (e.g. backing down the PID output if the reading moves

towards the setpoint). The derivative response is proportional to the rate

of change of the PV as seen between two consecutive PV updates. If the

rate of change goes to zero (i.e. stable process variable), then the

Derivative output also goes to zero. Increasing the derivative setting will

cause the control system to react more strongly to changes in the PV.

Most practical control systems use a very small or no derivative setting.

This is because the Derivative Response is highly sensitive to noise in the

process variable signal and relies on the PV to be fairly proportional to

the PID output changes, which the Streaming Current reading is generally

not. If used, the Update Delay time should be set closer to the process

lag time (which is the time needed for the analyzer to respond to a

change in chemical dosage).

Update Delay:

00:00:02

The Update Delay setting determines the frequency by which the Integral

Output value is calculated. Increasing this time (e.g. going from 2 to 5

seconds) will slow down the PID output adjustments, and vice versa.

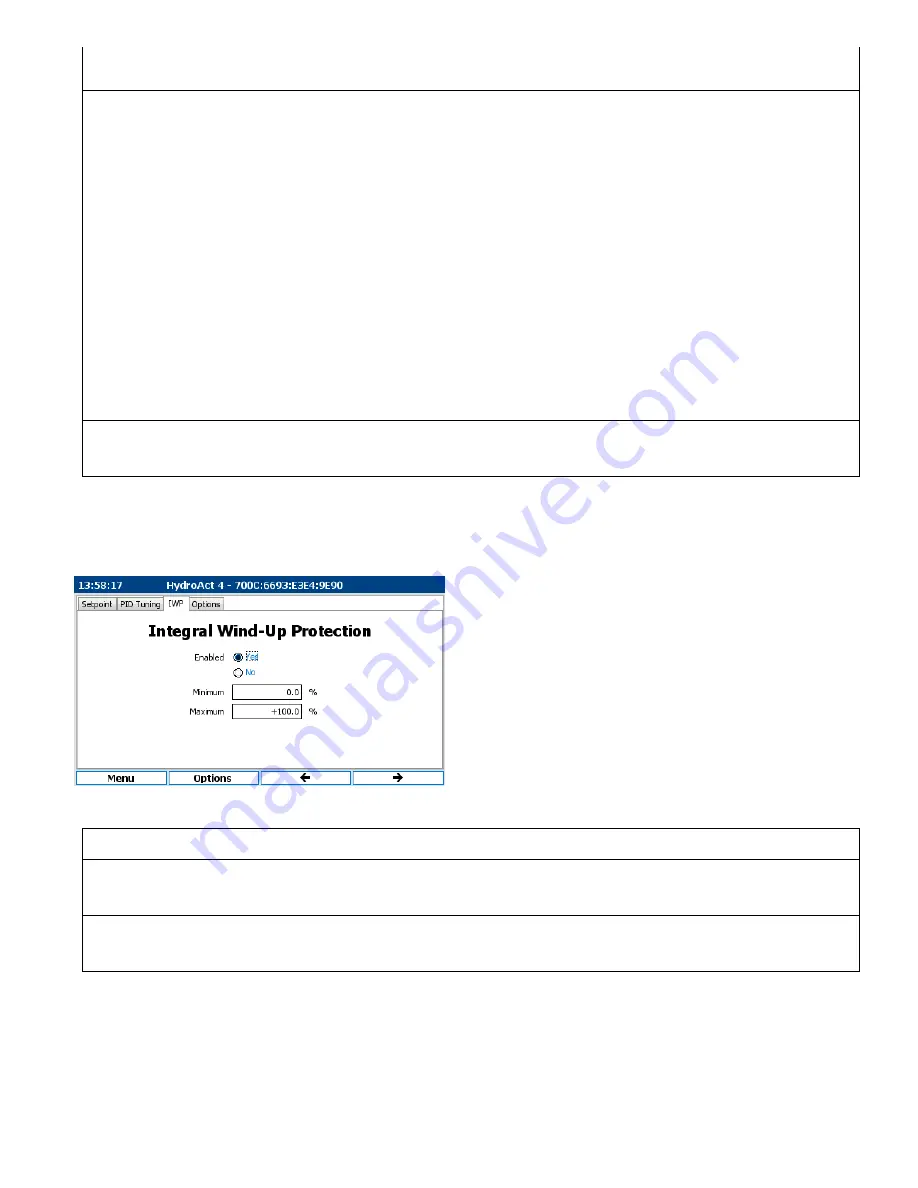

Options>Setup>PID Setup (To access the IWP tab, press the far right Function button, which is the button just

below the Right Arrow shown at the bottom of the display)

Parameter

Factory Setting

Notes

Enabled:

Yes

Leave this set for Yes.

Minimum:

0%

If the Flow pacing feature is disabled, this must be set to match the

Minimum Output Limit (discussed on page 12). When the Flow pacing

feature is enabled, this must be set for -100% (note: negative 100).

Maximum:

100%

If the Flow pacing feature is disabled, this must be set to match the

Maximum Output Limit (discussed on page 12). When the Flow pacing

feature is enabled, this must be set for +100% (note: positive 100).