12

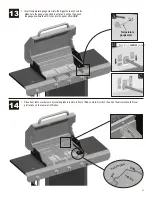

Burner Flame Check

• Remove cooking grates and flame tamers. Light burners, rotate

knobs from

HIGH

to

LOW

. You should see a smaller flame in

LOW

position than seen on

HIGH

. Perform burner flame check

on sideburner, also. Always check flame prior to each use. If

only low flame is seen refer to "Sudden drop or low flame" in

the

Troubleshooting Section

.

HIGH

LOW

Match-Lighting

▲

Do not lean over grill while lighting.

1. Open lid.

Turn

ON

gas at LP cylinder.

3.

Push in and turn far right or far left burner knob to the

HIGH

burner lights and stays lit.

4.

Light adjacent burners in sequence by pushing knobs in and

turning to the

HIGH

position.

Turning Grill Off

• Turn all knobs to the

OFF

position. Turn LP cylinder

OFF

by

turning hand-wheel clockwise to a full stop.

Ignitor Check

• Turn gas off at LP cylinder.

Press and hold electronic ignitor

button. "Click" should be heard and spark seen each time

between each collector box or burner and electrode. See

"Troubleshooting"

if no click or spark.

Valve Check

• Important: Make sure gas is off at LP cylinder before

checking valves

. Knobs lock in

position. To check

valves, first push in knobs and release, knobs should spring

back. If knobs do not spring back, replace valve assembly

before using grill. Turn knobs to

LOW

position then turn back to

position. Valves should turn smoothly.

Hose Check

•

Before each use, check to see if hoses are cut or worn or kinked.

Replace damaged hoses before using grill. Use only

valve/hose/regulator specified by manufacturer.

General Grill Cleaning

• Do not mistake brown or black accumulation of grease and

smoke for paint. Interiors of gas grills are not painted at the

factory

(and should never be painted)

. Apply a strong solution

of detergent and water or use a grill cleaner with scrub brush

on insides of grill lid and bottom. Rinse and allow to completely

air dry.

Do not apply a caustic grill/oven cleaner to painted

surfaces.

•

Plastic parts:

Wash with warm soapy water and wipe dry.

s

Do not use citrisol, abrasive cleaners, degreasers or a

concentrated grill cleaner on plastic parts. Damage to and

failure of parts can result.

• Porcelain surfaces:

Because of glass-like composition, most

residue can be wiped away with baking soda/water solution or

specially formulated cleaner.

Use nonabrasive scouring powder

for stubborn stains.

• Painted surfaces:

Wash with mild detergent or nonabrasive

cleaner and warm soapy water. Wipe dry with a soft

nonabrasive cloth.

• Stainless steel surfaces:

To maintain your grill’s high quality

appearance, wash with mild detergent and warm soapy water

and wipe dry with a soft cloth after each use. Baked-on grease

deposits may require the use of an abrasive plastic cleaning

pad. Use only in direction of brushed finish to avoid damage.

Do not use abrasive pad on areas with graphics.

• Cooking surfaces:

If a bristle brush is used to clean any of

the grill cooking surfaces, ensure no loose bristles remain on

cooking surfaces prior to grilling. It is not recommended to

clean cooking surfaces while grill is hot.

OFF

OFF

CAUTION

If ignition does NOT occur in 5 seconds, turn the

burner controls OFF, wait 5 minutes and repeat the

lighting procedure. If the burner does not ignite with

the valve open, gas will continue to flow out of the

burner and could accidently ignite with risk of injury.

Turn controls and gas source or tank OFF when not

in use.

WARNING

Sideburner Ignitor Lighting

▲

Do not lean over grill while lighting.

1. Open sideburner lid.

Turn

ON

gas at LP cylinder.

2.

Turn sideburner knob to the

HIGH

position, push and hold

ELECTRONIC IGNITOR

button.

3.

If sideburner does NOT light within 5 seconds, turn knob to

OFF

, wait 5 minutes, then

Sideburner Match Lighting

1. Open sideburner lid.

Turn

ON

2.

Place lit match near burner.

3.

Turn sideburner knob to the

Be sure burner lights and

stays lit.

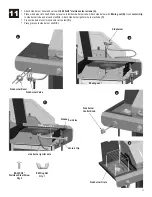

2.

Place match into match holder (hanging from side panel of

grill). Light match; then light burner by placing match through

the match light hole on right or left side of grill.

HIGH

position.

gas at LP cylinder.

repeat lighting procedure.

position, depending on match light hole selected. Be sure

NOTE: Your grill may NOT be equipped with a Sideburner!