100722 - 3500 Lb. (1588 kg) WiNch

ASSEMbLY

10

NOTicE

Terminals coming in contact with metal will cause a

direct short, possibly causing solenoid/contactor and/

or battery damage.

install the Rocker Switch

1. Decide which handlebar the rocker switch will be

mounted on. (The rocker switch is usually installed

on the left handlebar).

2. Use a piece of electrical tape (not provided) around

the handlebar to help prevent rotation of the mount.

3. Tighten the rocker switch in place. DO NOT

overtighten or tighten/clamp over any hoses or

cables.

4. Once the rocker switch is mounted, the wires can

be routed back to where the solenoid/contactor is

located.

5. Make sure the handlebars have full range of motion

and then secure the rocker switch’s cable with the

supplied cable ties.

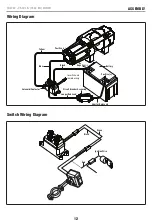

Wiring the Winch

cAUTiON

NEVER

route electrical cables across any sharp edges,

through and/or near moving parts, or near parts that

may become hot.

cAUTiON

Battery cables should NOT be drawn tight. Leave some

slack for cable movement.

NOTicE

You may need to use a test light to locate a suitable

wire. The wire should only have power when the key is

in the ON position.

NOTicE

Depending on the location of the solenoid/contactor,

you may need to use the black and red cables in place

of the yellow and blue, and the yellow and blue in place

of the red and black.

1. See the Wiring Diagram on the following page for

these following steps. Connect the yellow and blue

cables to the motor terminals on the winch. (Yellow

to the positive (+) terminal of the motor. Blue to

the negative (-) terminal of the motor). Tighten the

terminal nuts on the motor. DO NOT over tighten.

Route the other ends to the solenoid/contactor

location.

2. Connect the yellow and blue cables to the solenoid/

contactor (yellow to yellow and blue to blue).

DO NOT tighten nuts.

3. Connect the red and black cables to the solenoid/

contactor (red to red and black to black). DO NOT

tighten nuts. Route the other ends to the vehicle’s

battery.

4. Connect the shorter red lead to the positive (+)

terminal of the vehicle’s 12 volt battery. Connect

the other longer red lead to the solenoid/contactor.

Use the supplied cable ties to attached the circuit

breaker assembly where convenient.

5. Connect the rocker switch to the solenoid/contactor

(black to black and green to green).

6. Splice the end of the red wire on the rocker switch,

to an ignition (keyed) controlled power source using

the supplied wire tap.

7. Once all wiring is connected to the solenoid/

contactor it can then be mounted using the supplied

M6 hardware.

8. Tighten the solenoid/contactor terminal nuts.

DO NOT over tighten.

9. Connect the black lead to the negative (-) terminal of

the vehicle’s 12 volt battery.

10. Place all terminal boots over terminals and secure

all cables with cable ties or electrical tape (not

included).