100380 - REAR TiNE TiLLER

TiLLiNG TiPS AND TECHNiqUES

21

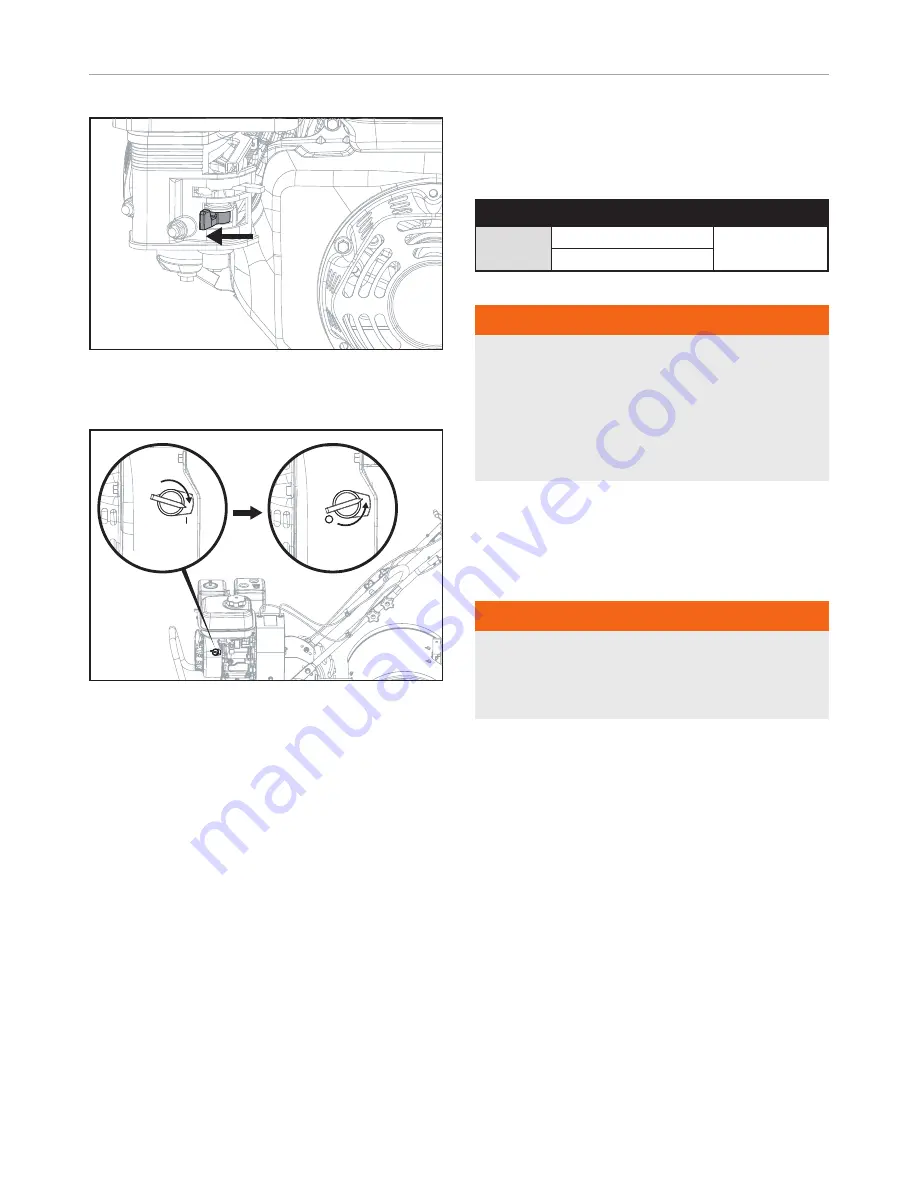

2. Turn the fuel valve to the “OFF” position.

3. Let the engine run until fuel starvation has stopped the

engine. This usually takes a few minutes.

4. Turn the engine switch to the “OFF” position.

OFF

ON

Operation at High Altitude

The density of air at high altitude is lower than at sea level.

Engine power is reduced as the air mass and air-fuel ratio

decrease. Engine power and generator output will be reduced

approximately 3½% for every 1000 ft. of elevation above

sea level. This is a natural trend and cannot be changed by

adjusting the engine. At high altitudes increased exhaust

emissions can also result due to the increased enrichment of

the air fuel ratio. Other high altitude issues can include hard

starting, increased fuel consumption and spark plug fouling.

To alleviate high altitude issues other than the natural power

loss, CPE can provide a high altitude carburetor main jet.

The alternative main jet and installation instructions can be

obtained by contacting our Technical Support Team. Installation

instructions are also available in the Technical Bulletin area of

the CPE website.

The part number and recommended minimum altitude for the

application of the high altitude carburetor main jet is listed in

the table below.

In order to select the correct high altitude main jet it is

necessary to identify the carburetor model. For this purpose,

a code is stamped on the side of the carburetor. Select the

correct high altitude jet part number corresponding to the

carburetor code found on your particular carburetor.

Carb. Code high alt. Jet Part Number min. altitude

Z530610

16161-Z010310-0000

3000 ft. (914 m)

6000 ft. (1829 m)

16161-Z050210-0000

WARNiNG

Operation using the alternative main jet at elevations lower

than the recommended minimum altitude can damage the

engine. For operation at lower elevations, the originally

supplied standard main jet must be used. Operating the

engine with the wrong engine configuration at a given

altitude may increase its emissions and decrease fuel

efficiency and performance.

TiLLiNG TiPS AND TECHNiqUES

Tilling Depths

WARNiNG

Before tilling, contact your telephone or utilities company

and inquire if underground equipment or lines are used

on your property. Do not till near buried electric cables,

telephone lines, pipes or hoses.

Avoid pushing down on the handlebars in an attempt to force

the tiller to dig deeper. Doing so takes the weight off the

powered wheels, causing them to lose traction. Without the

wheels helping to hold the tiller back, the tines will attempt to

propel the tiller – often causing the tiller to skip rapidly across

the ground. (Sometimes, slight downward pressure on the

handlebars will help get through a particularly tough section

of sod or unbroken ground, but in most cases this wont be

necessary.)

Avoid trying to dig too deeply too quickly, especially when

busting sod or when tilling soil that hasn’t been tilled for some

time. Use shallow depth regulator settings (only an inch or two

deep) for the first passes through the soil. With each succeeding

pass, dig another inch or two deeper. (Watering the area a few

days prior to tilling will make the tilling easier, as will letting the

newly worked soil set for a day or two before making a final,

deep tilling pass.