27

Care of Your Opener

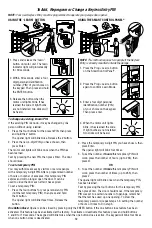

LIMIT AND FORCE ADJUSTMENTS:

Weather conditions may cause some

minor changes in door operation

requiring some readjustments,

particularly during the fi rst year of

operation.

Pages 21 and 22 refer to the limit and

force adjustments. Only a screwdriver

is required. Follow the instructions carefully.

Repeat the safety reverse test (Adjustment Step 3,

page 23) after any adjustment of limits or force.

MAINTENANCE SCHEDULE

Every Month

• Manually operate door. If it is unbalanced or binding,

call a trained door systems technician.

• Check to be sure door opens and closes fully. Adjust

limits and/or force if necessary. (See pages 21 and 22.)

• Repeat the safety reverse test. Make any necessary

adjustments. (See Adjustment Step 3.)

Two Times a Year

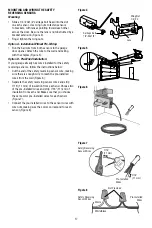

• Check chain tension. Disconnect trolley fi rst. Adjust if

necessary. (See page 7.)

Every Year

• Oil door rollers, bearings and hinges. The opener does

not require additional lubrication. Do not grease the

door tracks.

Every Three to Four Years

• Use a rag to wipe away the existing grease from the

garage door opener rail. Reapply a small layer of white

lithium grease to the rail.

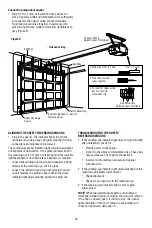

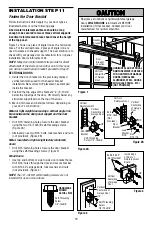

To Open the Door Manually

The door should be fully closed

if possible. Pull down on the

emergency release handle and lift

the door manually. To reconnect

the door to the opener, press the

door control push button.

The

lockout feature

prevents

the trolley from reconnecting

automatically, Pull the emergency

release handle down and back

(toward the opener). The door

can then be raised and lowered

manually as often as necessary.

To disengage the lockout feature,

pull the handle straight down. The

trolley will reconnect on the next

UP or DOWN operation.

To prevent possible SERIOUS INJURY or DEATH from

a falling garage door:

• If possible, use emergency release handle to

disengage trolley ONLY when garage door is

CLOSED. Weak or broken springs or unbalanced

door could result in an open door falling rapidly and/

or unexpectedly.

• NEVER use emergency release handle unless garage

doorway is clear of persons and obstructions.

• NEVER use handle to pull door open or closed. If

rope knot becomes untied, you could fall.

LOCKOUT POSITION

Trolley

Release

Arm

Emergency

Release Handle

(Down and Back)

MANUAL DISCONNECT

POSITION

Trolley

Release

Arm

Emergency

Release

Handle

(Pull Down)

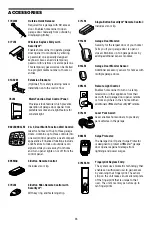

FORCE CONTROLS

LIMIT CONTROLS