27

MB Pool & spa heater

185, 265 & 405 Models

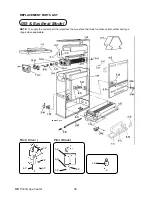

PILOT REMOVAL AND CLEANING

1. Disconnect pilot tubing, and wires from

gas

valve.

2. Remove pilot assembly from burner tray.

3. Remove pilot from bracket.

4. Remove pilot injector and clean with

wire or small brush.

CAUTION!

Do

not

enlarge hole in pilot orifi ce.

5. Reverse above procedure to re-install.

HEAT EXCHANGER REMOVAL

1. Shut water, gas and electricity off, close

valves and relieve pressure, remove relief

valve. Remove side inspection panels.

2. Remove top holding screws.

3. Remove draft diverter, lift and remove top

and

fl ue collector. Remove inspection

panels.

4. Loosen bolts and disconnect fl ange nuts

on inlet-outlet header, loosen union(s)

at gas pipe and slide boiler away from

piping until studs clear the header.

5. Lift heat exchanger straight up using

caution not to damage refractory.

6. Reverse above procedure to reinstall.

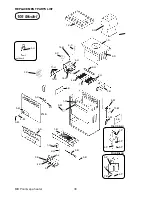

055, 105 & 155 Models

HEAT EXCHANGER REMOVAL

1. Shut water, gas, and electricity off, close

valves and relieve pressure.

2. Drain heat exchanger.

3. Loosen and remove fl ange bolts.

4. Remove fl ange and inlet/outlet pipes from

the

header.

5. Remove outdoor stackless top or indoor

stack top from unit.

6. Remove jacket top, fl ue collector, and

baffl es.

7. Remove upper front jacket panel, and

disconnect wires at toggle switch.

8. Remove capillary bulb from inlet/outlet

header.

9. Disconnect press switch tube from return

header.

10. Disconnect hi-limit wire from thermostat,

and pressure switch. Remove overheat

thermostat capilliary & phial.

11. Lift heat exchanger straight up from

combustion chamber, using caution not to

damage

refractory.

12. Reverse above procedure to re-install.

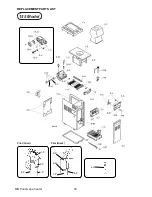

All Models

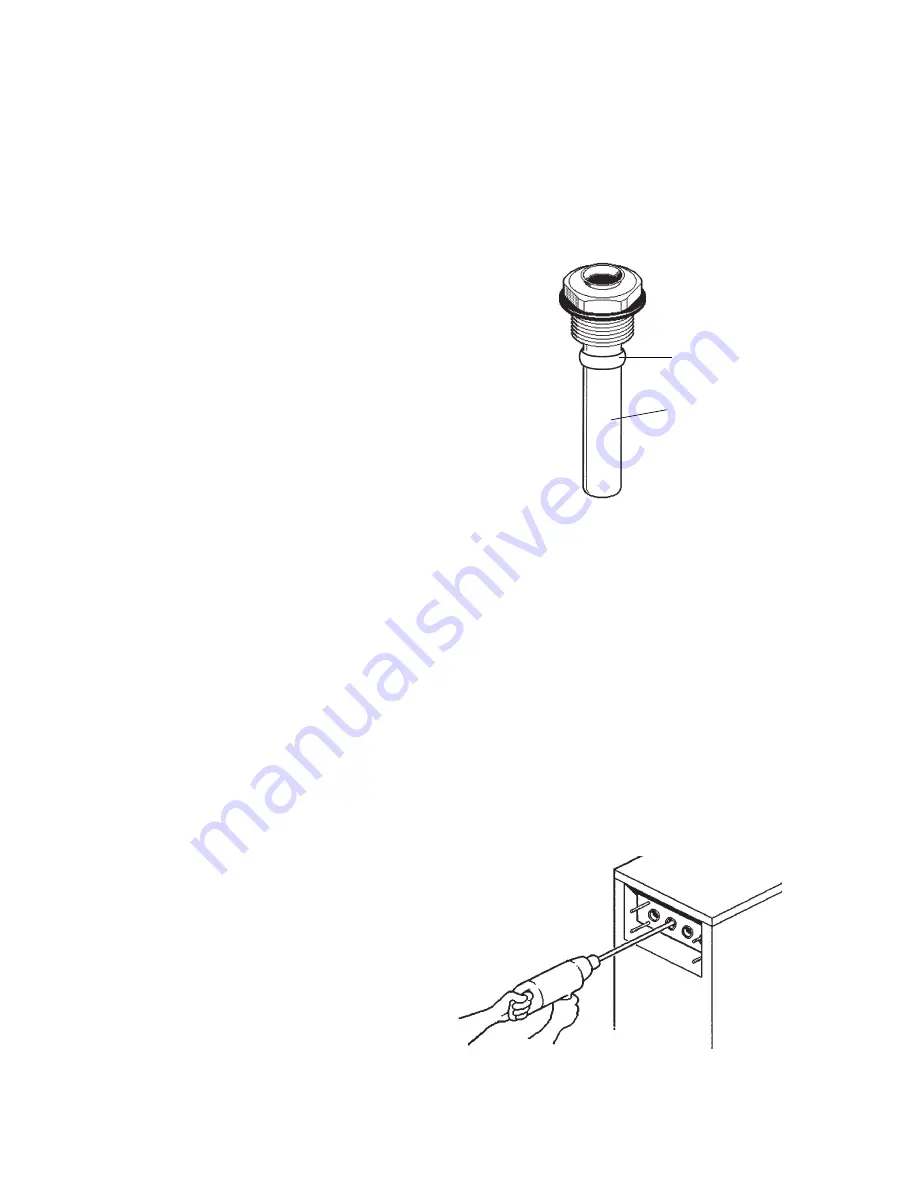

CONTROL IMMERSION WELL REPLACEMENT

1. Shut water off to heater and drain heat

exchanger.

2. Remove jacket top panel.

3. Remove old control well with bushing and

sleeve, with 7/8" wrench or socket.

4. Slip "o" ring gasket over control well and

install

in

header.

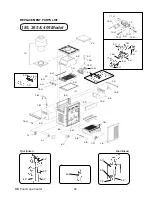

TUBE CLEANING PROCEDURE (Typical)

Establish a regular inspection schedule, frequency

depending on local water condition and severity of

service. Do not let the tubes clog up solidly. Clean

out deposits over 1.5 mm in thickness.

It is preferable to remove the heat exchanger and the

in/out header for better visibility through the tubes

and to be sure the ground-up lime dust does not get

into the system,

After reaming, mount the wire brush in place of the

auger and clean out debris remaining in the tubes.

Another method is to remove the heat exchanger,

ream tubes and immerse heat exchanger in non-

inhibited de-scale solvent.

Well Assembly

Olive