13

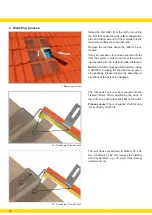

9 - Adjusting the 2-C groove profile

After the hammer head screw

has been inserted

into the 2-C groove profile, it will be rotated 90°

once more until the hammer head plate engag-

es its profile.

For more efficient adjustment of the 2-C groove

profiles, you should initially only tighten the

hammer head screws hand-tight. Via the grating

on the 2-C groove profiles, a maximum height

compensation

of 40 mm may take place.

The torque of the M10 nuts per hammer head

screw is 50 Nm.

10 - Connecting the 2-C groove profile

Connecting links are available for connecting

the 2-C groove profiles.

The connecting link can already be fastened

onto one side of the 2-C groove profile.

Join both 2-C groove profiles to one another.

Now place the connecting link from above into

the centre of the profile and turn the hammer

head screws clockwise at 90°. Now fasten the

nuts tightly.

Please ensure:

The slot on the screw must be

at a 90° angle to the direction of the rails.

11 - Mounting the protective covers

Both sides of the profile openings should then

be closed. Insert the 2-C groove protective cov

-

er into the hollow section of the 2-C groove pro

-

file. Light taps with a rubber hammer will finally

set the protective cover in the profile.

It is recommended to provide the profiles with

the protective covers whilst still on the floor.

ca. 250-400 mm

Summary of Contents for CENPAC 3 Series

Page 1: ...www centrosolar com www centrosolar co uk CENPAC Mounting instructions CENPAC 3 x CENPAC 5 x...

Page 2: ......

Page 4: ...4...

Page 22: ...Notes 22...

Page 23: ......