35.

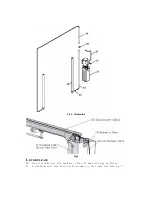

Lower lift to the floor. Pull and release lock release handle while watching idler column lock.

Adjust threaded sleeve cable adjuster nuts until idler column lock disengages and engages fully.

When properly adjusted, the idler column lock should just come to rest against the back of the

column when engaged and fully out against the tab when disengaged.

IMPORTANT

: IF IDLER SIDE LOCK PAWL DOES NOT FULLY DISENGAGE, DAMAGE

MAY RESULT TO IDLER SIDE CARRIAGE AND OR CABLE SYNCHRONIZING SYSTEM.

36.

Tighten and trim wire ties.

37.

Snap lock cover over each lock assembly.

O

PERATION PROCEDURE

S

AFETY NOTICES AND DECALS

This product is furnished with graphic safety warning labels, which are reproduced on page 3 of

these instructions. Do not remove or deface these warning labels, or allow them to be removed or

defaced. For your safety, and the safety of others, read and understand all of the safety notices and

decals included.

O

WNER/EMPLOYER RESPONSIBILITIES

The owner/employer shall

make sure that all lift operators are qualified and trained in the safe use and

operation of the lift in accordance with the manufacturer

’

s operating instructions. They also shall

display the lift manufacturer

’

s operating instructions and maintenance schedule in a conspicuous

location and area, convenient to the operator.

The owner/employer shall

establish procedures to periodically inspect and maintain the lift in

accordance with the lift manufacturer

’

s suggestions. The employer shall insure that the lift inspector and

maintenance personnel are qualified and that they are adequately trained in these procedures. The

employer shall maintain these periodic inspection and maintenance records.

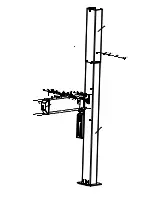

L

IFTING A VEHICLE

1)

Insure that the lifting arms are parked, out to full drive thru position.

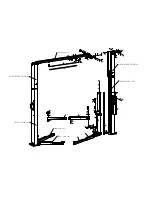

2)

Position the vehicle in the service bay so that the vehicle

’

s center of gravity is on a line between the

two columns, and so the vehicle is centered between the two columns.

DO NOT EXCEED 2500 POUNDS PER ARM.

DO NOT ATTEMPT TO LIFT THE VEHICLE WITH ONLY TWO ARMS, AS THIS WILL

VOID THE WARRANTY

INSURE THAT THE HIGHEST POINT ON THE VEHICLE WILL CONTACT THE

OVERHEAD LIMIT SWITCH BAR

DO NOT PLACE THE VEHICLE IN THE SERVICE BAY BACKWARDS.

3)

Position the arms and adapters so all four pads contact the vehicle simultaneously.

The vehicle should remain level during lifting.

4)

Raise the lift until all four wheels are off the ground. Test the stability of the vehicle by attempting

to rock the vehicle. Check adapters for secure contact with vehicle lift points. If the vehicle seems

unstable, lower the lift and readjust the arms. If the vehicle is stable, raise the vehicle to a height a

few inches above the desired working height.

5)

Lower the vehicle until the safety latches on both columns engage. The vehicle should remain level

when both latches are engaged. If one side engages and the other continues to descend, stop

lowering the vehicle, raise it several inches, and try again to engage both latches.

Always lower lift into locks before entering the area beneath the vehicle.

Always use safety stands when removing or installing heavy components.