Do not attempt to raise a vehicle on the lift until the lift has been

correctly installed and adjusted as described in this manual.

R

ECEIVING

The shipment should be thoroughly inspected as soon as it is received. The signed bill of lading is

acknowledgement by the carrier of receipt in good condition of shipment covered by our invoice.

If any of the goods called for on this bill of lading are shorted or damaged, do not accept them until the

carrier makes a notation on the freight bill of the shorted or damaged goods. Do this for your own

protection.

NOTIFY our company AT ONCE if any hidden loss or damage is discovered after receipt.

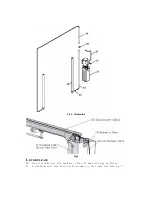

Component Packing List

DESCRIPTION

QTY

DESCRIPTION

QTY

Power Column Ass

’

y

1

Synchronizer Cable

2

Idler Column Ass

’

y

1

Hydraulic Hose Pack

1

Power Column Extension

1

Power Lock Cover

1

Idler Column Extension

1

Idler Lock Cover

1

Overhead Ass

’

y

1

Hardware Box

1

Rear Arm Ass

’

y

2

Front Arm Ass

’

y

2

I

NSTALLATION

IMPORTANT

: Always wear safety glasses while installing lift.

T

OOLS

(MINIMUM REQUIRED)

a.

Banding Cutter

b.

Tape measure, 16ft

c.

Chalk line

d.

4ft level

e.

10

”

adjustable wrench

f.

Standard open end wrenches 7/16

”

-15/16"

g.

Needle nose pliers

h.

Hammer drill

i.

2lb hammer

j.

Torque wrench: 150 foot pounds minimum

k.

12 ft. Step ladder

l.

Anti-Seize lubricant (for arm pins)

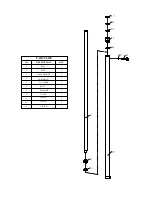

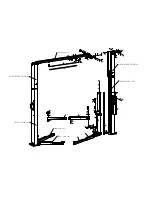

L

AYOUT

1.

Layout the service bay according to the architect

’

s plans or owners instructions (see Fig 1b). Be

certain that the proper conditions exist.

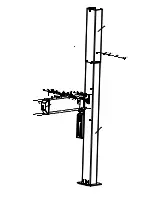

2.

Assemble column extension to column using M12

×

30 Hex bolt. Repeat for opposite column and

extension.

3.

Using the Overall Width(C) as a guideline, chalk two parallel (line 1 and line 2) on the concrete

floor within 1/8 inch tolerance.

4.

Determine the location of the Column Ass

’

y on either chalk line and mark the base plate dimension

Overall Width(L) .