10

4.1) Fuel mixture preparation

Risk of explosion or fi re, petrol is extremely fl ammable, handle with caution.

Risk of intoxication, avoid inhalation of petrol vapours.

Risk of irritation, avoid prolonged and repeated contact with skin.

The rail saw has a 2-stroke air cooled engine which runs on an oil-petrol mix; for the correct

dosage of oil use the measure supplied, according to the following proportions:

1:50 (2 %) of specialist synthetic 2 stroke engine oil (e.g. 5 litres of petrol,

0.1 litres of oil).

Alternatively:

1:33 (3 %) of other 2 stroke engine oils for air cooled engines classifi ed

according to JASO FB/ISO EGB (e.g. 5 litres of petrol, 0.15 litres of oil).

Always use good quality 2 stroke engine oil and a minimum 90 octane Petrol.

Mix petrol and oil together well and prepare only enough for immediate use as the mixture will

age and if several weeks old may cause engine damage.

Always use the correct fuel mixture to avoid:

1 - Smoking engine and dirty spark plug, should the mixture be too oil rich.

2 - Excessive overheating with consequent seizing of the engine, should the mixture be

oil defi cient.

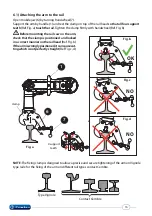

4.2) Refuelling

Always refuel with the engine swiched off .

Place the rail saw on its side with the tank cap facing upwards.

Using a non-spill fuel container, slowly add the mix, making sure not to spill it;

Always perform refuelling in an well-ventilated area away from the work zone, keeping

a safe distance of at least 3 metres (10 ft).

Use only a non-spill fuel container.

In the event of spillage during topping up, carefully dry the engine before turning it on. Fully

tighten the fuel cap.