10

25

Before servicing or maintenance, stop the motor and disconnect the plug

from the electric source

After fi rst 10 oerating hours, proceed with sump oil change, as follows:

(Ref. to Fig. 28)

– Remove the cap with the magnetic insert (21).

– Remove oil fi ller cap (07).

– Make sure that all the oil comes out by slightly tilting the drill.

– Clean up the cap (21) (see § 13.1.2).

– Reassemble the cap (21).

– Fill the sump with oil to the level indicator (see § 13.1.1) using the oil supplied with the

drilling machine; it will be necessary to use about 4.7 fl oz oil.

– Replace the fi ller cap (07).

13.1) ORDINARY MAINTENANCE OF THE MACHINE (Ref. to Figs. 24 and 28)

Every 20 hours of operation

13.1.1) Topping up oil

With the drill switched off and placed on a fl at surface, check the oil level in the crankcase

by looking through the appropriate transparent inspection cover (13).

The level must be approximately half way up the cover; if the level is low top up the oil

by unscrewing the cover (07) at the top of the crankcase and adding the quantity of oil

required.

Only use the oil grade recommended in § 1.

Never use regenerated or used oil.

The oil must be clean.

13.1.2) Removal of metallic residue

from the crankcase

When the drill is positioned as shown

in Fig. 24 unscrew the appropriate cap,

with magnetic insert (21) on which any

metallic residue will have collected.

Carefully clean the magnetic insert

with a clean rag and screw it back in

the appropriate housing.

▲

!

FIG. 24 – REMOVAL OF

METALLIC RESIDUE

21

13. MAINTENANCE

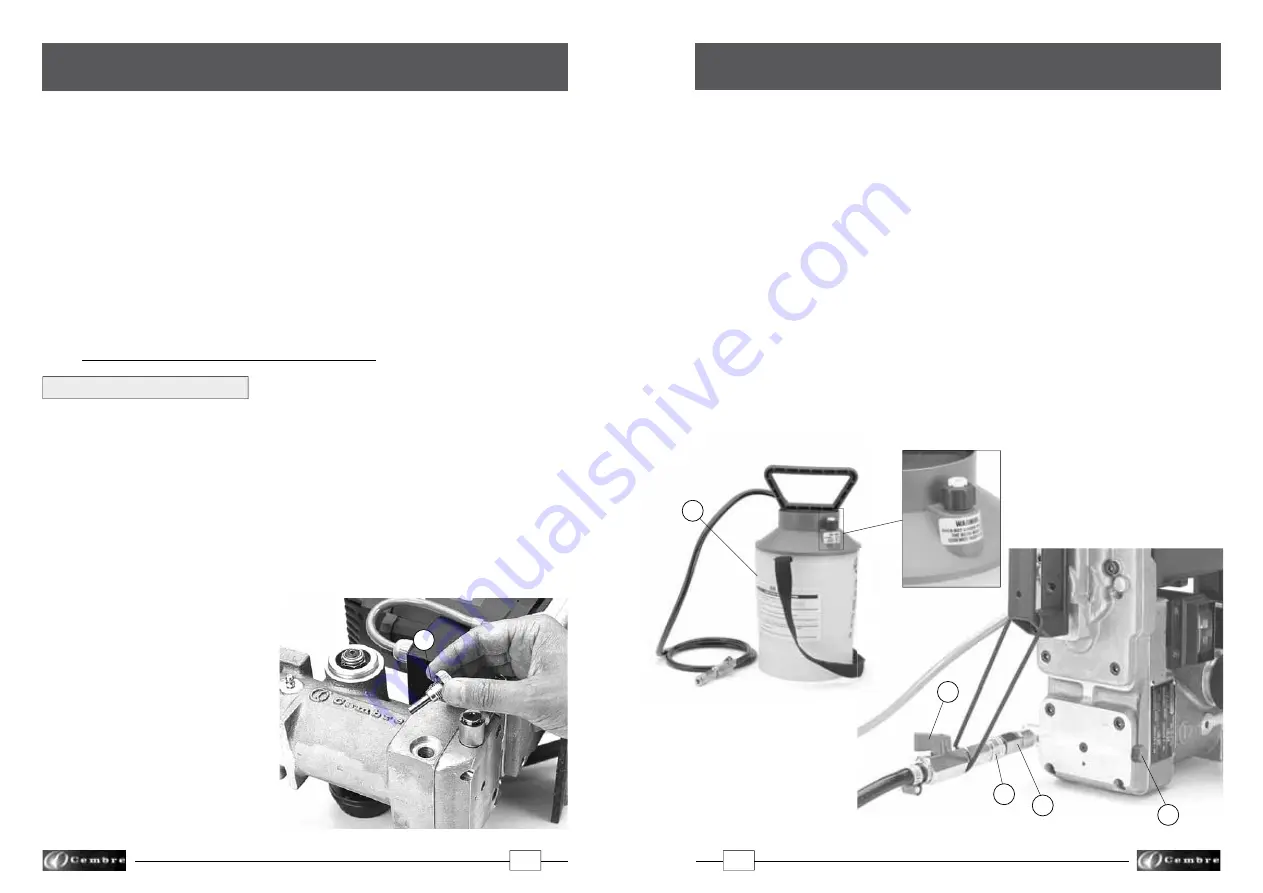

The type SR5000 coolant unit consists of a tank complete with tube and maximum pressure

valve (01), fi tted with a pump device for pressurisation, which must be connected to the

attachment (35) on the drill by means of its quick-coupling (03).

The delivery and shut-off of the lubrocoolant are controlled automatically, when drilling

with a broach cutter, from the position of the guide bit; when drilling with a spiral bit,

delivery and shut-off of the fl uid must be effected manually by operating the tap (02).

The use of the lubrocoolant supplied by

Cembre

, in the recommended concentrations,

guarantees optimum use of the drilling tools.

Consumption of the lubrocoolant depends both on the variable degree of opening

of the tap (02) and the inner pressure of the tank: it is therefore advisable to open

the tap a little when the tank is at maximum pressure, while it must be fully opened

when the pressure in the tank is low.

When using the coolant system, pay careful attention to the instructions on the tank label.

Warning:

●

When the tank is not under pressure, check that the bush on the maximum pres-

sure valve is screwed right down.

●

To fi ll tank with lubrocoolant, turn handle anticlockwise approximately 2 turns to

release handle locking mechanism. Remove handle/piston assembly from tank.

02

03

35

17

01

Detail of the

max pressure valve

FIG. 3 – COOLANT UNIT

01 – Tank complete with hose

and max. pressure valve

02 – Tap

03 – Quick-coupling

17 – Vent valve

35 – Attachment valve

4. Type SR5000 COOLANT UNIT (Ref. to Fig. 3)