48

EN

NewTom GO 2D/3D

- TECHNICAL MANUAL

TROUBLESHOOTING

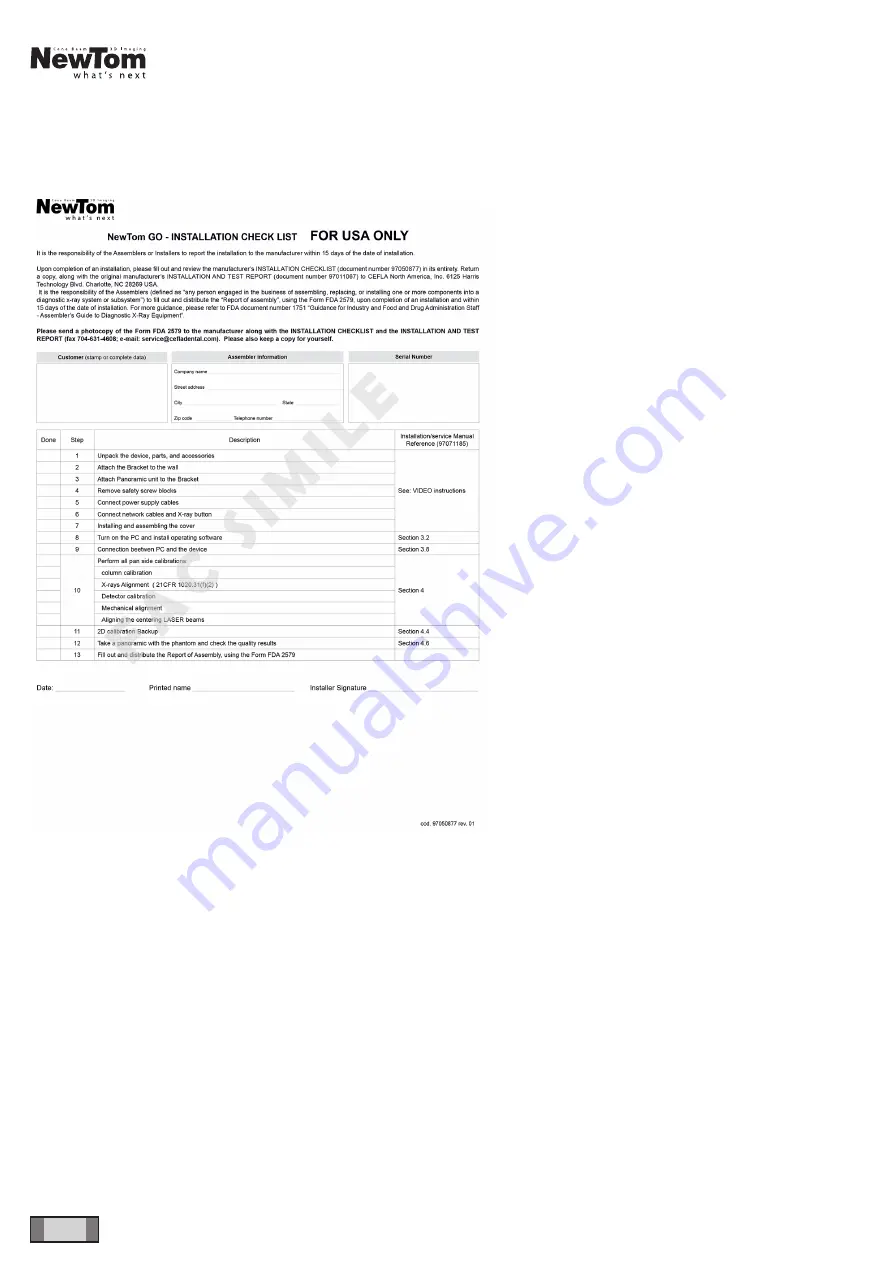

7. INSTALLATION CHECK LIST (FOR USA ONLY)

It is the responsibility of the Assemblers or Installers to report the installation to the manufacturer within 15 days of the

date of installation.

Upon completion of an installation, please

fill out and review the manufacturer’s

INSTALLATION CHECKLIST (document

number 97050897, PDF file available on

the CD ROM supplied with the device or on

extranetdentale.cefla.it

) in its entirety. Return

a copy, along with the original manufacturer’s

INSTALLATION AND TEST REPORT

(document number 97011067) to CEFLA

North America, Inc. 6125 Harris Technology

Blvd. Charlotte, NC 28269 USA.

It is the responsibility of the Assemblers

(defined as “any person engaged in the

business of assembling, replacing, or installing

one or more components into a diagnostic

x-ray system or subsystem”) to fill out and

distribute the “Report of assembly”, using

the Form FDA 2579, upon completion of an

installation and within 15 days of the date of

installation. For more guidance, please refer

to FDA document number 1751 “Guidance for

Industry and Food and Drug Administration

Staff - Assembler’s Guide to Diagnostic X-Ray

Equipment”.

Please send a photocopy of the Form

FDA 2579 to the manufacturer along with

the INSTALLATION CHECKLIST and the

INSTALLATION AND TEST REPORT:

fax 704-631-4608 or

e-mail: [email protected].

Please also keep a copy for yourself.

In the event of a technical maintenance, if components bearing a serial number are replaced, an authorized technician

must:

• repeat all the steps prescribed by the installation checklist,

• fill out a new installation report bearing the new serial number of the replaced component,

• send the the new installation report and installation checklist to the manufacturer,

• fill out and distribute the Report of Assembly, using the Form FDA 2579 - for a list of exceptions to reporting

requirements, please refer to 21CFR 1020.30(d)(2).

Summary of Contents for NewTom GO 2D

Page 1: ...Cod 97071219 Rev 01 01 2017 NewTom GO 2D 3D technical manual EN...

Page 2: ......

Page 4: ...2 EN NewTom GO 2D 3D TECHNICAL MANUAL CONTENTS...

Page 37: ...35 EN NewTom GO 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION...

Page 40: ...38 EN NewTom GO 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION PIN 4 signal X ray ON...

Page 41: ...39 EN NewTom GO 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION...

Page 45: ...43 EN NewTom GO 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION...

Page 47: ...45 EN NewTom GO 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION 5 5 MONOBLOC AREA...

Page 51: ......

Page 52: ......