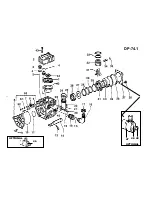

2) Diaphragm Replacement

- Drain the oil from the pump by removing cap under the crankcase. Rotate the shaft to remove excess oil.

- Remove the pump heads one by one.

- Use a hex wrench to remove the diaphragm locknut: remove the nut, retaining washer, diaphragm and support

washer.

- If you removed the piston sleeves, replace them one at a time in their previous position (best mark them when

removing).

- Insert the new diaphragm on the piston and install it with its nut. Use these tightening torques.

• 10 mm.=36 ft.-lbs.

• 12 mm.=50 ft.-lbs.

• 12 mm.=72 ft.-lbs.

The diaphragms should be replaced with the piston at its bottom DP and the edges inserted perfectly into the groove

all the way around.

- Replace the heads and attach them with their bolts.

- Refill pump with oil through the glass and rotate the shaft to distribute oil and fill to proper level. Repeat all the

checks described above in the section “Checks to make before using the pump.”

- Check oil level with the pump running with no pressure until all air bubbles have been vented.

- When the air has been bled off, close the cap on the oil sight tube.

- After the first inspection of the oil level as above, check once more the oil level with the pump running with pres-

sure.

3) Oil Change

Normally the oil is changed whenever the diaphragm is changed. Depending on work conditions, oil should be

changed every 500 hours.

The oil change procedure is described in number 2 above.

✮

FOR TROUBLESHOOTING CHART, SEE BACK COVER

✮

5