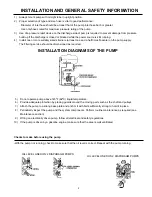

Coupling to Agricultural Machinery

1) Check that the PTO of the machine does not exceed the max rpm shown on the pump plate.

2) If the PTO is synchronized with the motor speed, consult the service manual to get gear number and rpm

corresponding to the max pump rotation speed.

3) When the rpm of the PTO is higher than the max speed, use the suggested reduction gear.

4) Disconnect the PTO when moving with pump out of service; if that is impossible, then disengagement should

be provided.

5) Disconnect the PTO when changing direction.

Coupling to electric motors and gasoline engines

1) For direct coupling always use the suggested reduction gear.

2) For coupling with pulley, check alignment of the two pulleys.

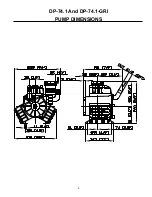

Maximum Transmission Ratio:

= K

Pump RPM

After determining K, you can establish the motor or pump pulley diam.:

Motor Pulley Pitch Diam.: m.p.ø =

= K

K

Pump Pulley Pitch Diam. - p.o.ø =

Motor Pulley Pitch ø x K

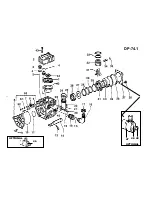

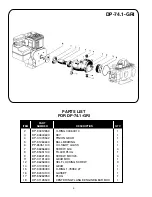

MAINTENANCE FOR DIAPHRAGM PUMPS

Routine maintenance on the pump includes changing the diaphragms, oil, valve assembly, o-rings, all of which are

normal wear parts.

1) Valve assembly and O-Rings Replacement

Occasionally debris can cause the valves to not seat properly or damage o-rings. To check for this problem please

follow these steps:

-

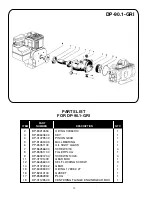

Remove the valve cover (consult the exploded drawing of the pump), remove the valves, check for debris and

wear as well as o-rings.

-

Replace necessary parts and reassemble.

-

Repeat for all valves. Consult the parts list for the valve kit or o-ring kit part numbers.

4

Motor RPM

Pump Pulley Pitch Diameter