Page

16

of

22

3.4 About the tests

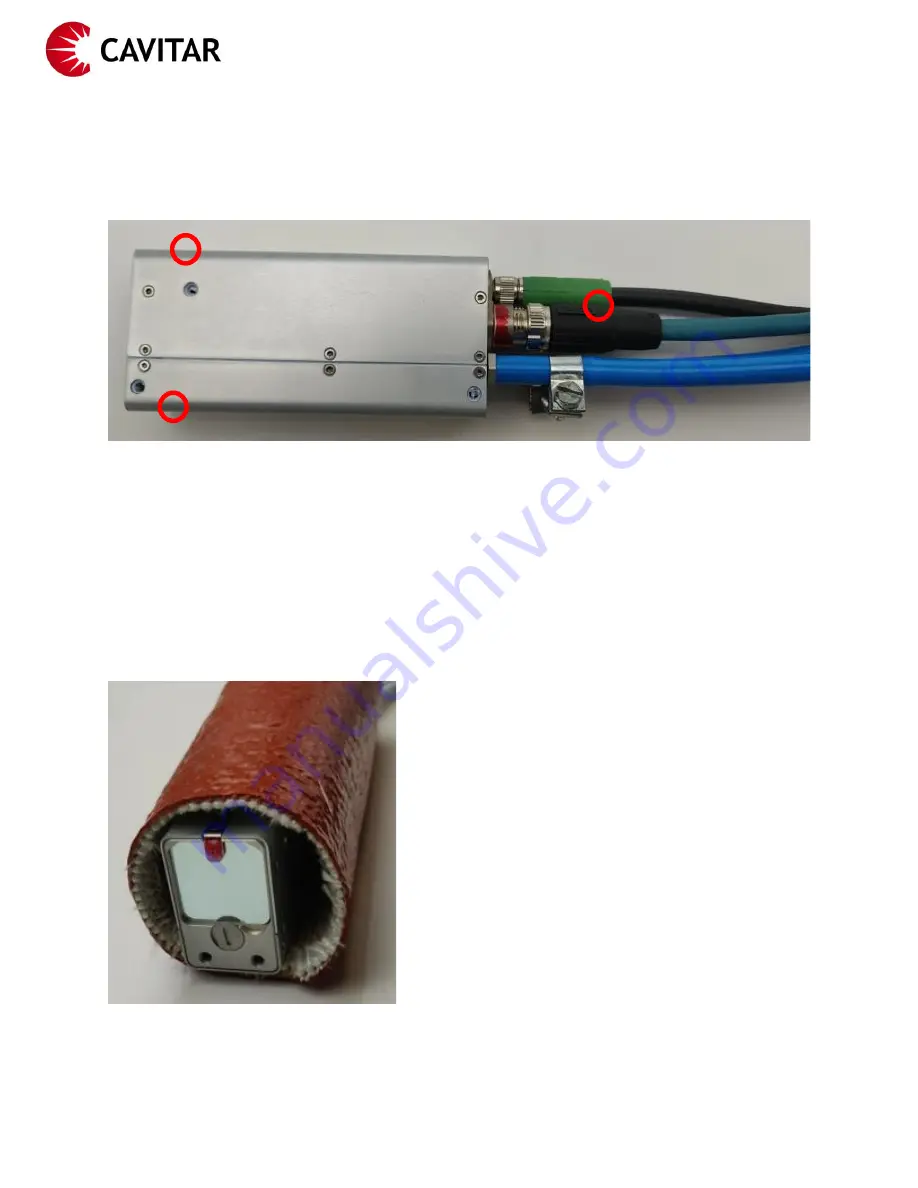

The tests were carried out by putting the camera and cables inside an oven and by logging temperature

values from different locations (Fig. 3.10). Also the ambient temperature inside the oven was measured.

Fig. 3.10. Temperature measurement points.

All tests were realized with 25 m long inlet and outlet cooling hoses (50 m total loop length) with inner

diameter of 6 mm. In the tests of Sections 3.5 and 3.6 the cables were insulated and the camera was not

insulated (see Figs. 3.2, 3.3 and 3.6-3.8) except in the recirculating chiller tests, which were done also with

the camera insulated (see Fig. 3.5). In the case of combined air and liquid cooling (Section 3.7) the

insulation consisted of one pyrojacket (no thermosleeves applied) and the interface between camera

housing and pyrojacket was not sealed (see Fig. 3.11) to let the air flow through the system. Cooling hose

twisting around cables (Fig. 3.2) and aluminium foil (Fig. 3.3) were applied also in this test.

Fig. 3.11. Insulation arrangement for combined air and liquid cooling.

Body top measurement point

Body bottom measurement point

Cables Temperature measurement point