RS232C Communication Kit

4

RS board

Lower body

of operation unit

Socket

RS board

Circuit board

Plug in

Plug in

Connector cable

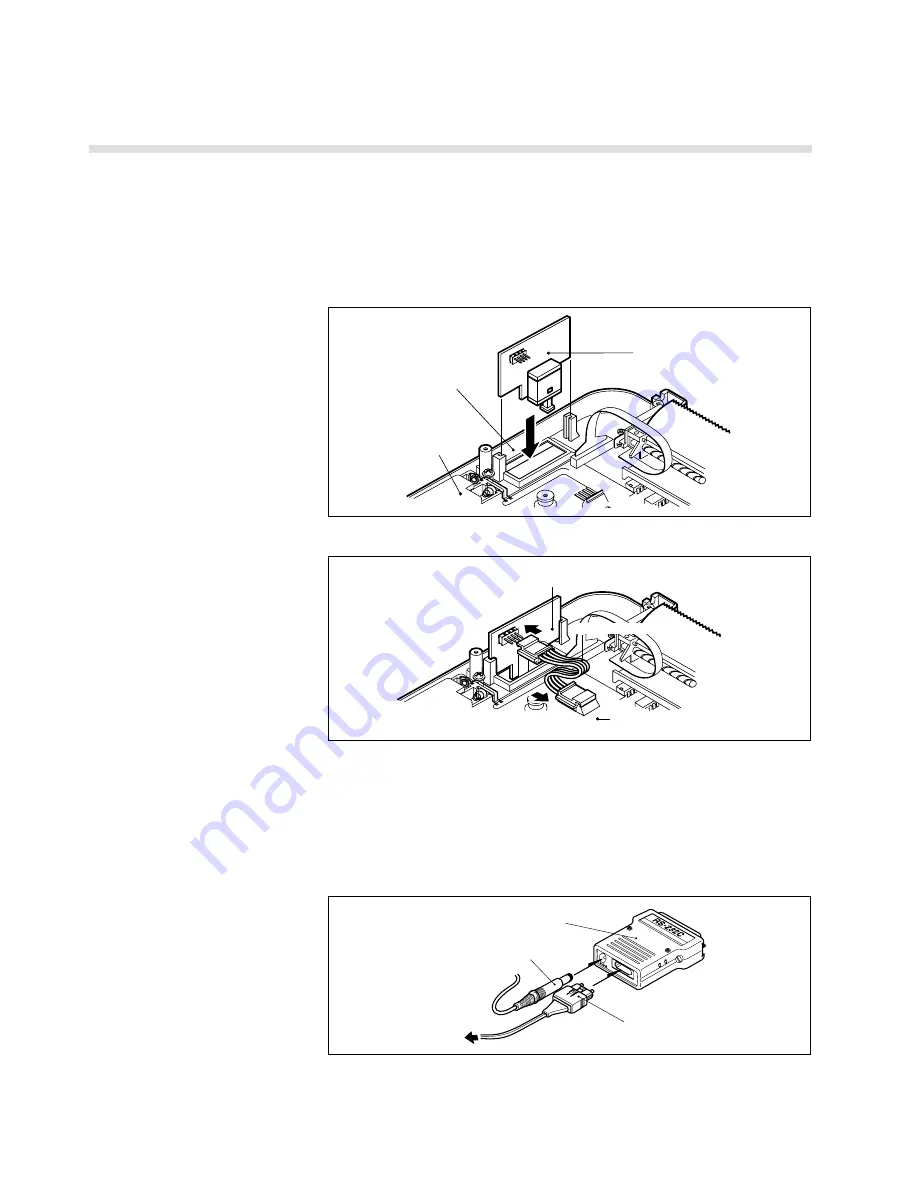

1-2) Assembling RS232C communication kit

1-2-a) Installing RS board

4

in

operation unit

・

Remove the 8 screws that are holding the upper body on the rear panel of

the operation unit. Open the unit's upper body as shown in the figure

below.

・

Referring to the figure, place the RS board so that its mounting holes are

aligned with mounting holes in the unit and the black optical cable

connector is located at the rear end of the unit. Secure the board with the 2

screws supplied.

・

Connect the board to the unit via the connector cable supplied.

KIS-00RC000-P

DC

IN

OU

T

IN

5V

Optical cable connector

Converter

AC Adapter connector

To operation unit

1-2-b) Connecting optical cable

to operation unit

・

Close the upper body and secure it with the 8 screws.

• Remove the covers from the optical connector and converter. Insert the

optical cable connector and the AC Adapter connector into the converter

socket with the correct orientation. (If the optical cable connector is badly

oriented, it will not plug into the converter.)