6MAINTENANCE

0446 924 001 GB

-11 -

© Eutectic AB2020

5.3 Wire feed pressure

Start by making sure that the wire moves smoothly through the wire guide. Then set the

pressure of the wire feeder's pressure rollers. It is important that the pressure is not too

great.

To check that the feed pressure is set correctly, you can feed out the wire against an

insulated object, e.g. a piece of wood.

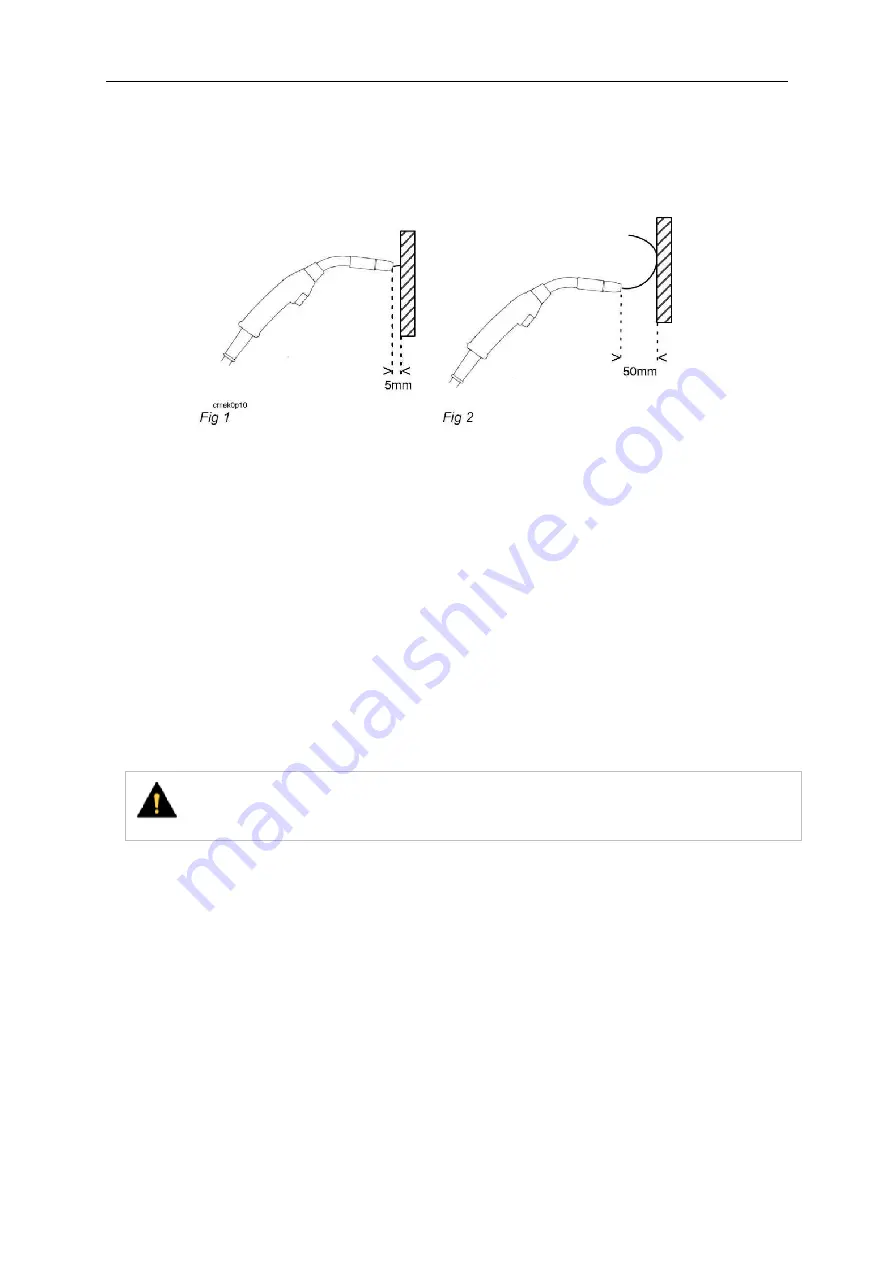

When you hold the gun approx. 5 mm from the piece of wood (Fig. 1) the feed rollers

should slip.

If you hold the gun approx. 50 mm from the piece of wood, the wire should be fed out

and bend (Fig. 2)

5.4 Wire inching

Wire inching is used to feed wire without welding voltage and gas flow. The wire is fed as long

as the button is depressed. Wire inching speed can be adjusted by the speed setting knob

CAUTION!

Before pressing the inching button make sure, the speed is set to the required

value.