16

4. ACCESSORY

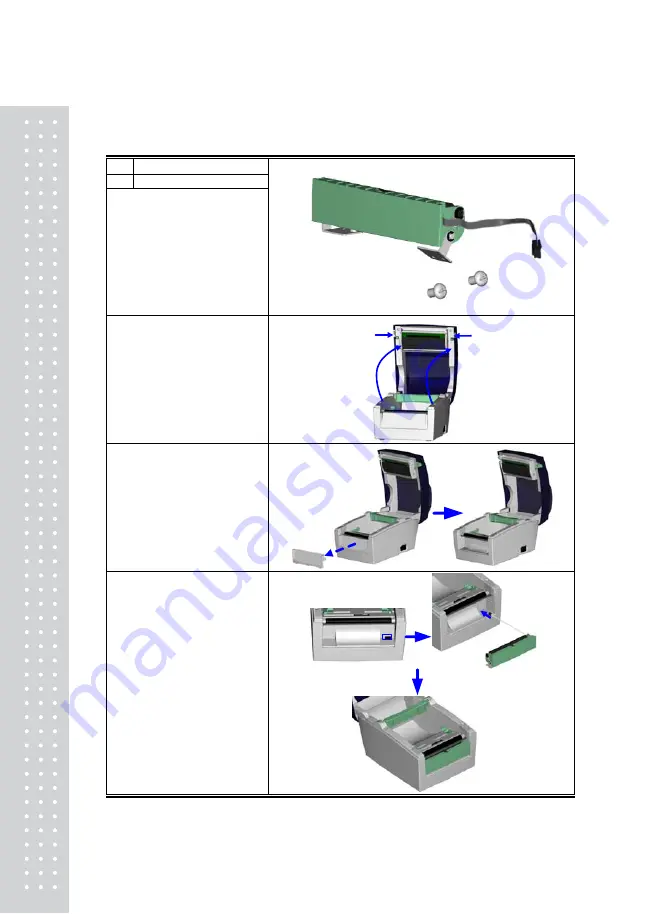

4-1. Stripper Module Installation

1 Stripper

Module

2 Screw

X

2

[Note1]

Please power off the printer

before installing the stripper

module.

[Note 2]

Label liner thickness is

recommended to be 0.06mm

±10% with basic weight 65g/

㎡

±6%.

2

1

1. Place the printer on a

horizontal surface and open

the Top Cover

2. Remove the Front Cover

Piece.

[Note1]

You can also use coin or

screwdriver to open the Front

Cover Piece.

3. Push the stripper connector

into printer through the cable

hole as shown in figure.

4. Place the Stripper on the

fillister. Align the Stripper with 2

notches on the fillister.

Summary of Contents for BP-DT-4

Page 1: ...2 ...

Page 27: ...28 MEMO ...

Page 28: ...29 MEMO ...

Page 29: ...30 MEMO ...

Page 30: ...31 31 뒷표지 뒷표지 ...