6

All factory-installed relief valves are lead-sealed to prevent cany

calibration change. The external relief valves must always be

vented to outside if the units are installed in a closed space. Refer

to the installation regulations, for example those of European

standard EN 378 and EN 13136. These pipes must be installed

in a way that ensures that people and property are not exposed

to vented refrigerant. As the fluids can be diffused in the air, ensure

that refrigerant is discharged away from building air intakes, relief

valves must be checked periodically. The valves must be checked

periodically.

The safety device shall be tested at least once a year to verify

good operation and cut out value.

An example of test procedure

without removing the pressure

switch

is given in Section 11.9 of this manual

.

If the relief valves are installed on a change-over manifold, this is

equipped with a relief valve on each of the two outlets. Only one

of the two relief valves is in operation, the other one is isolated.

Never leave the change-over valve in the intermediate position,

i.e. with both ways open (locate the control element in the stop

position). If a relief valve is removed for checking or replacement

please ensure that there is always an active relief valve on each

of the change-over valves installed in the unit.

All factory-installed relief valves are lead-sealed to prevent any

calibration change.

The external relief valves are designed and installed to ensure

damage limitation in case of a fire.

In accordance with the regulations applied for the design, the

European directive on equipment under pressure and in

accordance with the national usage regulations:

• These relief valves (and rupture disk if used) are not safety

accessories but damage limitation accessories in case of

a fire.

• The high pressure switches are the safety accessories.

The relief valve must only be removed if the fire risk is fully

controlled and after checking that this is allowed by local

regulations and authorities. This is the responsibility of the

operator.

When the unit is subjected to fire, safety devices prevent rupture

due to over-pressure by releasing refrigerant. The fluid may then be

decomposed into toxic residues when subjected to the flame:

• Stay away from the unit

• Set up warnings and recommendations for personnel in

charge to stop the fire.

• Fire extinguishers appropriate to the system and the

refrigerant type must be easily accessible.

The external relief valves must be connected to discharge pipes for

units installed in a room. Refer to the installation regulations, for example

those of European standards EN-378.

These standards include a sizing method and examples for

configuration and calculation. Under certain conditions they permit

connection of several valves to the same discharge pipe.

Carrier recommends using flexible hose to connect the relief valves

to discharge pipe. Special care shall be taken so that coupling to

discharge pipe is not creating mechanical stress on relief valve

connection.

These pipes must be installed in a way that ensures that people and

property are not exposed to refrigerant leaks. These fluids may be

diffused in the air, but far away from any building air intake, or they

must be discharged in a quantity that is appropriate for a suitably

absorbing environment (Note that the R1234ze(E) refrigerant is

heavier than air).

It is recommended to install an indicating device to show if part of

the refrigerant has leaked from the valve. The presence of oil at the

outlet orifice is a useful indicator that refrigerant has leaked. Keep

this orifice clean to ensure that any leaks are obvious.

The calibration of a valve that has leaked is generally lower than

its original calibration. The new calibration may affect the operating

range. To avoid a nuisance tripping or leaks, replace or re-calibrate

the valve.

Periodic check of the relief valves: See paragraph 1.3 “Maintenance

safety considerations”.

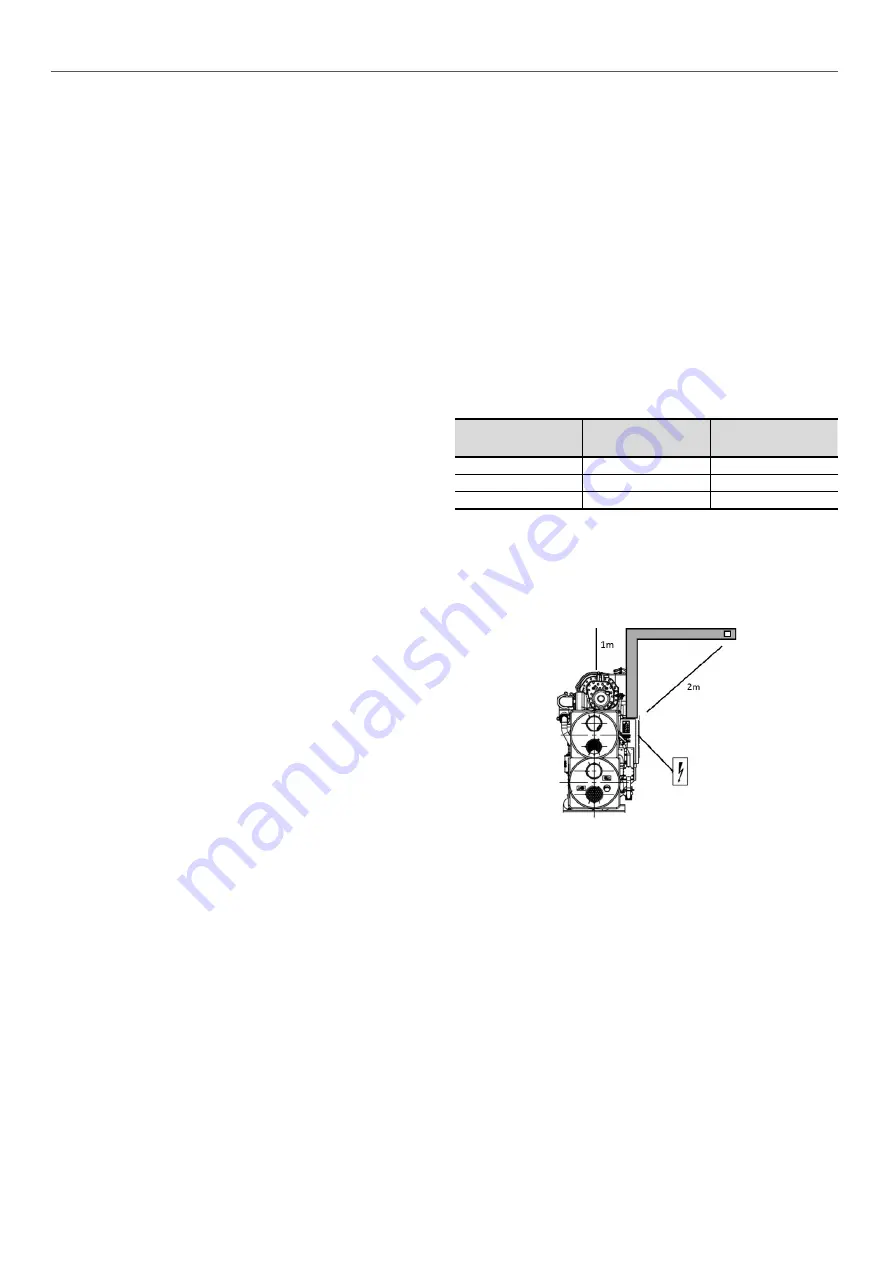

The electrical box must be supplied with fresh air source.

This must be done by connecting the interface on the top of the

electrical box with an air duct. The fresh air should be sucked from

outside the machinery room in an open air area. If this is not

possible, it is acceptable to suck fresh air inside the machinery

room but the following criteria must be respected regarding the

ventilation duct inlet:

• located at least one meter higher than the highest point of

the unit

• located at least 2 meters away from the unit

• The inlet air duct must be sized according to table below

(Maximum air duct pressure drop for a given air flow)

In addition, the following constraints must be fulfilled:

•

The junction between the air duct and the electrical box

interface must be tight

• The inlet air duct must be sized to guarantee below

maximum pressure drop in any operating condition

(including fooling)

61XWH model

Air flow (m

3

/h)

Air duct maximum

pressure drop (Pa)

3

40

10

5 / 7

60

20

10 / 14 / 15 / 17

120

40

•

The electrical box fan filter if any has to be serviceable in

order to be checked, cleaned and replaced if necessary.

•

The inlet of the duct should be equipped with a dust filter.

It’s filtering classification shall depend on dust occurrence.

G3 class per EN 779 is recommended.

Provide a drain in the discharge circuit, close to each relief valve,

to avoid an accumulation of condensate or rain water.

1 - INTRODUCTION