I N S T R U C T I O N S

For the installation and maintenance of D C 1 5 2 5 - D C 1 5 5 0

d e s u p e r h e a t e r s

IMI0049E.doc

Rev.0 20/08/14

20090 SEGRATE (MI)- via E.Fermi

EMAIL:

TEL.(02) 269912.1 - FAX.(02) 2692.2452

Page 14 of 16

9.7 RE-ASSEMBLY

Before refitting the valve, lubricate all the threads. Apply a thin layer of compound to the piston rings to

prevent scoring. Position the grooves in the piston rings in such a way that they are at 120° to each other.

Re-assemble the spray cylinder to the body extension. Use a fine abrasive paste to hone the seat of the

cylinder and the body extension. As the seal is metal on metal, a perfectly concentric area of the seat is

essential. Always use a new tightening ring. Position the spray cylinder so that it is correctly oriented (the

injected liquid must be in the same direction as the vapour flow), then tighten the tightening ring.

9.8 WELDING

Once re-assembled, weld the spray cylinder for improved safety. It is imperative that this operation be

undertaken by a skilled welder. A welding procedure specification is available from Carraro on request.

Both TIG and ARC welding are acceptable, and the recommended electrode material is ER NiCrMo3.

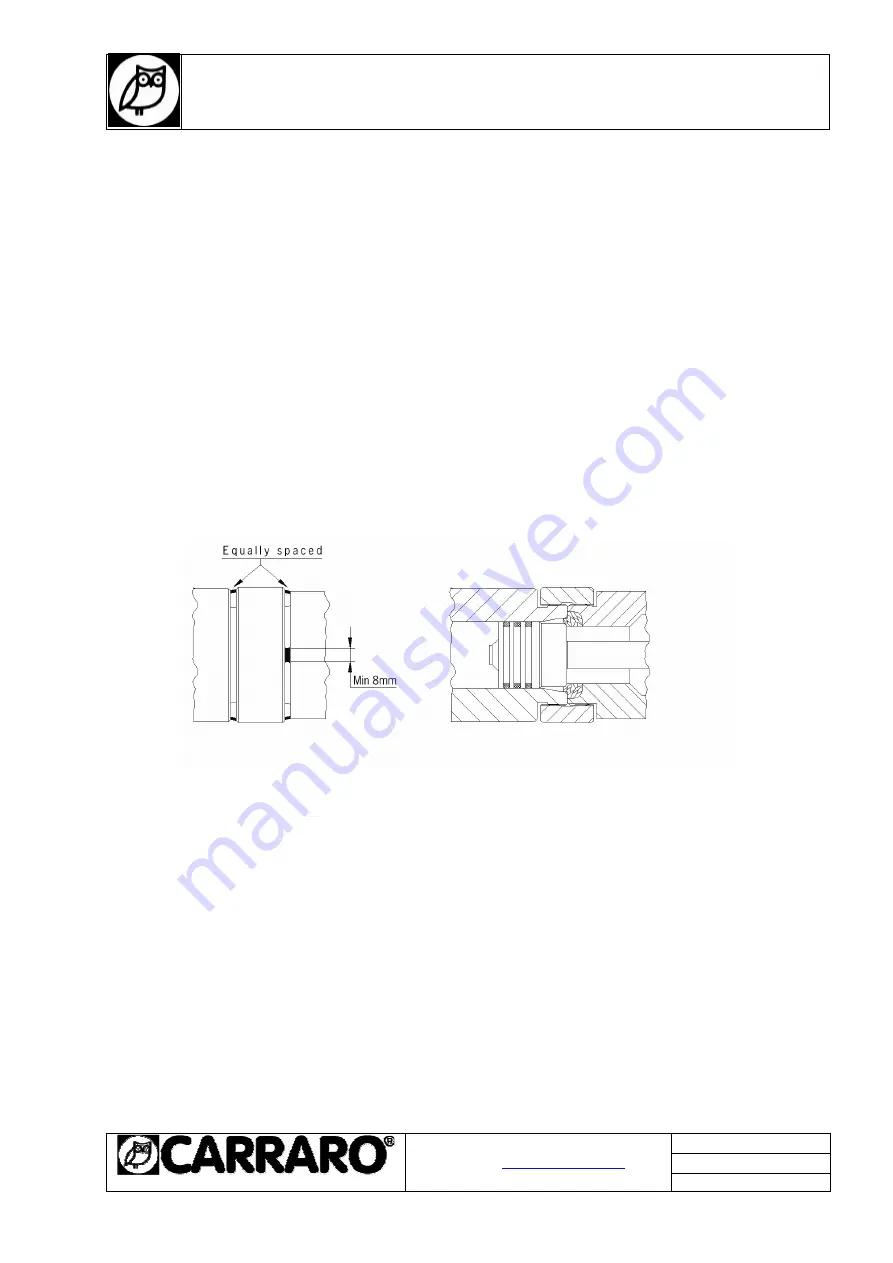

At least 2 tack welds are necessary. They must be 8 mm in length and diametrically opposed. One weld

must secure the fastener ring to the body extension, and the other must secure the spray cylinder to the

fastener ring. On completion, check the welding using appropriate penetrating liquids. There must be no

cracks. If necessary, grind and check again until the weld is satisfactory (see Fig. 8).

Fig. 8

9.9 RE-INSTALLATION

Refit the actuator to the desuperheater, referring to the data noted during disassembly when repositioning

the stem. Before re-installing the desuperheater check that the surfaces of the unit connection flanges are

completely clean. Insert the desuperheater in the vapour pipe and check that the nozzle is correctly

oriented, with the spray in the direction of the process gas flow. Lubricate the nuts and studs with a

suitable lubricant for operation temperatures and tighten uniformly, in accordance with the manufacturer’s

instructions. Before connecting the liquid supply line, flush the pipe and check that there are no

restrictions and no contamination.