EN

Remove tip and needle and

thoroughly clean.

Damaged or missing piston O

ring

Inspect and/or replace

Replace.

Blocked tip.

Replace or clean.

Use correct solenoid valve for

CYL air or fit quick exhaust valve

Air pressure to piston is not

being removed

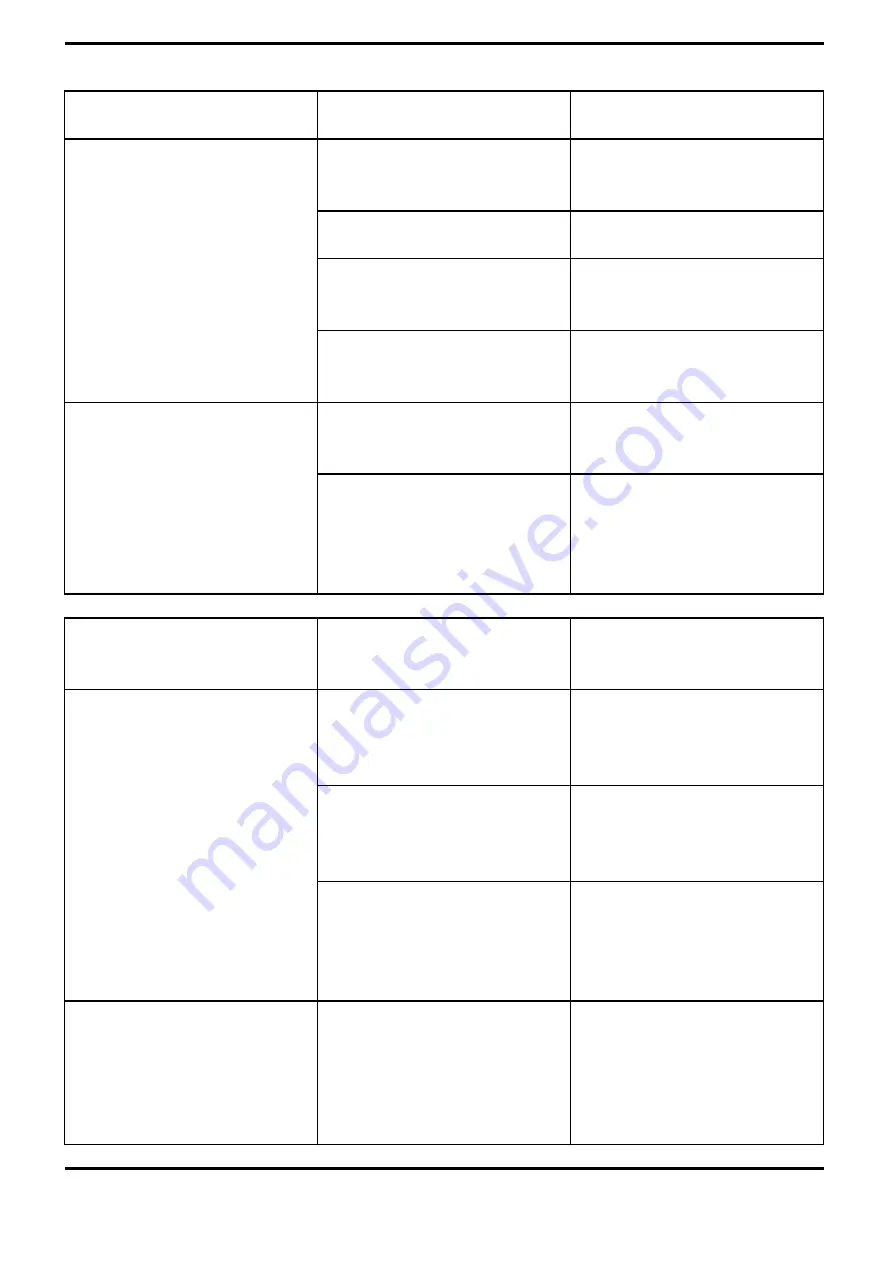

Will not spray.

Gun will not shut off.

CORRECTION

CAUSE

FLUID LEAKAGE FAULTS

Check air supply and air line

pressure.

Insufficient piston (CYL) air

pressure

Fluid pressure above gun max

working pressure.

Reduce fluid pressure.

Replace.

Needle seat internal surface

scored damaged or worn.

Check air supply and air line.

GENERAL FAULTS

CAUSE

CORRECTION

No cylinder air pressure at gun.

TROUBLESHOOTING MECHANICAL PERFORMANCE

Fluid needle external profile

damaged or worn.

Slow fluid leak from needle seat.

Contamination on needle or seat

mating surfaces preventing good

seal.

Thoroughly clean.

Major fluid leak or fluid jetting

from fluid tip or needle seat,

when gun is off.

Contamination on needle or seat

mating surfaces preventing good

seal.

SB-E-2-646 R1.1

17/28

www.carlisleft.com

Summary of Contents for Binks AG360 Series

Page 10: ...EN SPRAY GUN AND MANIFOLD INSTALLATION SB E 2 646 R1 1 10 28 www carlisleft com ...

Page 11: ...EN EXPLODED VIEW SB E 2 646 R1 1 11 28 www carlisleft com ...

Page 16: ...EN DISASSEMBLY NEEDLE PACKING SB E 2 646 R1 1 16 28 www carlisleft com ...

Page 23: ...EN FIXING LOCATIONS SB E 2 646 R1 1 23 28 www carlisleft com ...

Page 24: ...EN DIMENSIONS SB E 2 646 R1 1 24 28 www carlisleft com ...

Page 26: ...EN NOTES SB E 2 646 R1 1 26 28 www carlisleft com ...

Page 27: ...EN NOTES SB E 2 646 R1 1 27 28 www carlisleft com ...