30

ENG

Hecu

C

O

2

+0300085EN rel. 2.2 - 07.05.2019

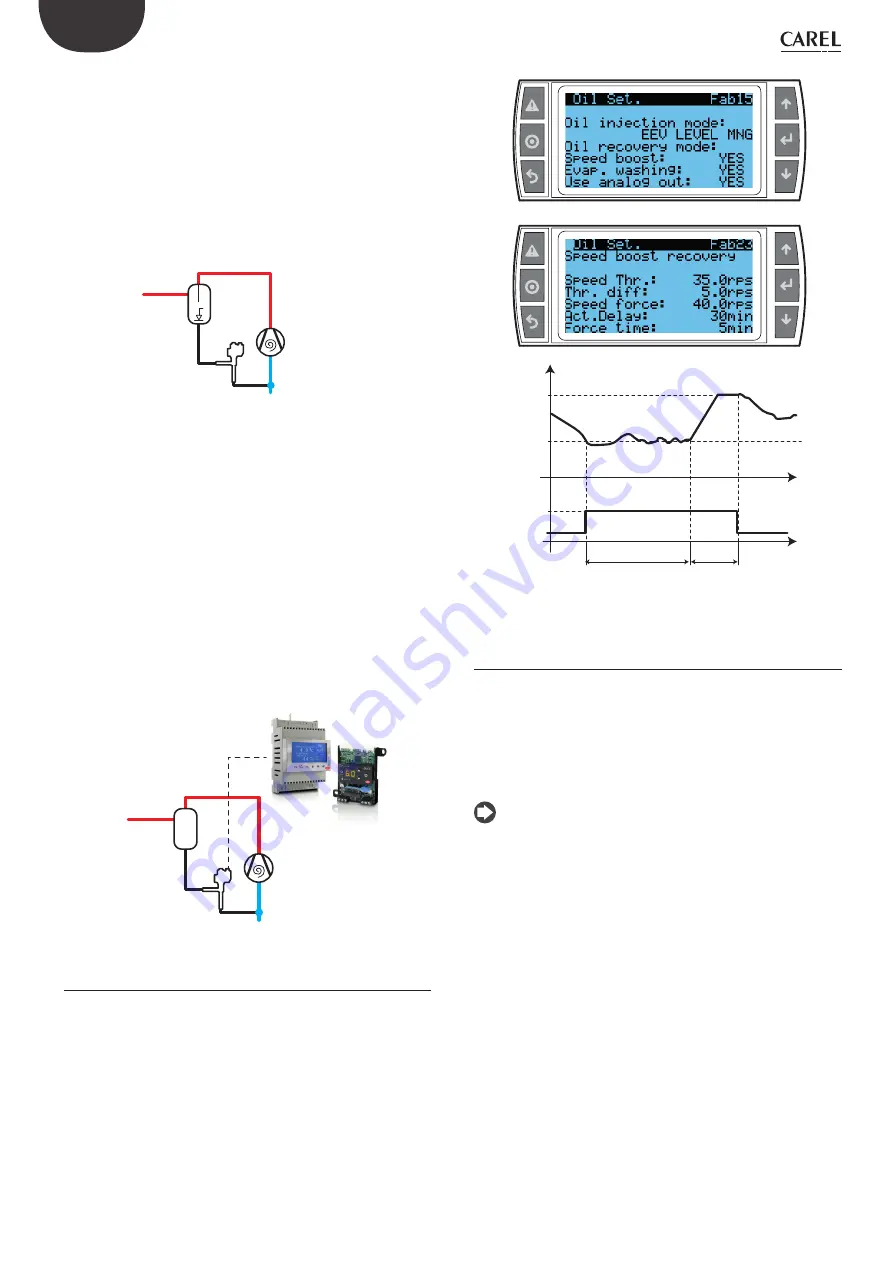

Electronic expansion valve (EEV LEVEL MNG)

This solution involves a CAREL expansion valve. The valve opening is

calibrated based on normal system operating conditions. This solution is

very effi

cient from an energy viewpoint, as it injects the exact quantity of

oil needed by the compressor. In order to use this function, an advanced

oil separator needs to be installed, featuring a level sensor that defi nes

three states via two digital inputs, confi gurable on

screens Faa55, Faa56

.

An advanced algorithm calculates valve opening based on the time that

elapses between the various states, comparing this against the previous

measurements. The objective is to replicate the oil level inside the

compressor by measuring the amount in the separator and keeping this

level stable over time.

3

advanced

oil separator

(double oil level)

EEV valve

BLDC

compressor

V

Fig. 6.q

On

screen Fab20

, two preventive thresholds can be set for the high and

low oil level (Emergency HL and LL). If the oil remains at this level for

the set time, the valve will open to the maximum (HL) or minimum (LL),

moving at 1 step/sec.

Electronic expansion valve controlled by external driver (EEV

COMP SPEED)

This solution features an expansion valve driven by an external driver

(EVDevo, EVD mini), confi gured as a positioner that receives the 0...10 V

control signal from the Hecu unit.

This is exploited when integrated drivers for the oil valve cannot be used

on Hecu CO2 as they are reserved for transcritical valves. Valve opening

is calibrated based on the BLDC compressor operating conditions (MT

or LT, not parallel), adjusted proportionally based on compressor speed.

A standard oil separator can be installed to exploit this function.

The parameters can be confi gured from screens Bad14 for assigning the

analogue output, and Fab15 to enablòe the function.

standard

oil separator

EEV valve

BLDC

compressor

V

Fig. 6.r

O

il speed boost

This function boosts the return of oil by operating the compressor at

a fi xed speed for a set time, thus recovering the oil spread along the

refrigerant circuit.

This override function is activated if the following conditions are true, see

screens Fab15, Fab23

:

•

Speed boost: YES

•

Compressor speed < minimum threshold

•

The previous conditions remain for a set time

Act. Delay

Force time

t

t

rps

Speed Force

Comp. Speed

Thr diff.

Speed Thr

Fig. 6.s

O

il Recovery Washing

Another function available on Hecu CO2 to assist oil return to the

compressor involves washing the evaporators.

This function uses serial

communication between Hecu

C

O

2 and the MP

X

PR

O

controllers,

and the electronic expansion valves on the evaporators

. The oil

recovery washing function sets the superheat set point to 0K for a

settable time t1 [default 3 minutes] in order to retrieve the oil spread

along the refrigerant circuit; the valve will thus open further, “washing”

the evaporator and fl ushing the accumulated oil back the compressor.

Note

: to make this function more eff ective, the electronic expansion

valve on the evaporator opens fully at the start of the recovery washing

cycle and then its position is controlled automatically based on the new

superheat set point.

td is the time at the end of a washing cycle for which compressor speed

remains fi xed, and valve opening returns to the same position as prior

to activation of the function [default 2 minutes]. If this value is set to 0,

at the end of a washing cycle the system will restart without overriding

compressor speed and keeping the valve at the previous opening

position for a set time. During a washing cycle, the following conditions

are set:

•

Oil recovery washing: ON

•

Smooth Line: OFF

•

P3: 0K

•

P7: -10K

•

St: -50°C

Summary of Contents for Hecu CO2

Page 2: ......

Page 4: ...4 ENG Hecu CO2 0300085EN rel 2 2 07 05 2019...

Page 6: ......

Page 61: ...61 ENG Hecu CO2 0300085EN rel 2 2 07 05 2019 9 2 Software revision history New version 3 0 012...

Page 62: ...62 ENG Hecu CO2 0300085EN rel 2 2 07 05 2019 Notes...

Page 63: ......