3-14

SmartBase MPC200/imageCLASS MPC200

Chapter 3: Assembly and Disassembly

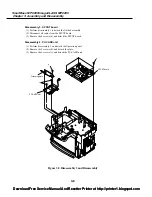

Disassembly 9. Contact sensor drive motor

(1) Perform disassembly 8, and detach the contact sensor.

(2) Loosen the screw (a), and push the pulley toward the inside to detach the contact sensor drive belt

from the gear.

(3) Remove the screw (b), and detach the shaft stopper.

(4) Remove the 2 screws (c), and detach the grounding plate.

(5) Remove the screw (d), and detach the contact sensor drive motor together with the plate.

(6) Remove the 2 screws (e), and detach the contact sensor drive motor from the plate.

Figure 3-9 Disassembly 9

Grounding plate

Contact sensor drive belt

a

Pulley

Contact sensor drive motor

Shaft stopper

d

e

b

c

Download Free Service Manual And Resetter Printer at http://printer1.blogspot.com