2-7

SmartBase MPC200/imageCLASS MPC200

Chapter 2: Technical Reference

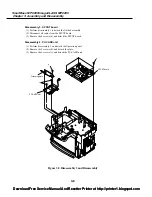

3.1.1 Carriage

The carriage holds one BJ cartridge in place. The carriage belt driven by the carriage motor (DC motor)

moves the carriage horizontally back and forth across the paper.

Regarding the carriage's position control, the initial position is detected when the carriage goes against

the right wall which is the home position.

After that, the carriage position is detected by reading the pulse from the encoder film.

The paper spacing position is read from the carriage position when the carriage goes against the left wall.

3.1.2 Purge section

The purge section, driven by a dedicated purge motor, consists of the wiper, pump, cap, and carriage

lock.

The wiper maintains the head face surface to ensure high-quality printing. The ink suction feature

enables the ink to be readily ejected from the nozzles.

When the BJ cartridge is not in use, the nozzles are protected by a cap, and the carriage is locked in

place.

The motor's running direction controls the ink suction operation or capping/wiping/valve open/closing

operation.

3.1.3 Paper feed section

The paper feed section consists of the paper feed components, paper transport section, and paper

discharge section.

Paper feed

Paper is picked up automatically from the auto sheet feeder.

The feeder is designed to accommodate various sizes of paper (as large as LGL), picking up individual

sheets and forwarding them to the feeding block.

Paper transport section

The paper feed section, driven by the paper feed motor, keeps the sheet of paper flat and horizontal on

the platen and rotates the feed roller to move the paper horizontally to and beneath the print head.

Paper eject section

After printing, paper is ejected onto the discharge tray by the eject rollers.

After the sheet of paper leaves the paper feed rollers, the eject rollers take over to eject the paper.

Download Free Service Manual And Resetter Printer at http://printer1.blogspot.com