2. LIST OF ERROR DISPLAY / INDICATION

Errors and warnings are displayed on the LCD.

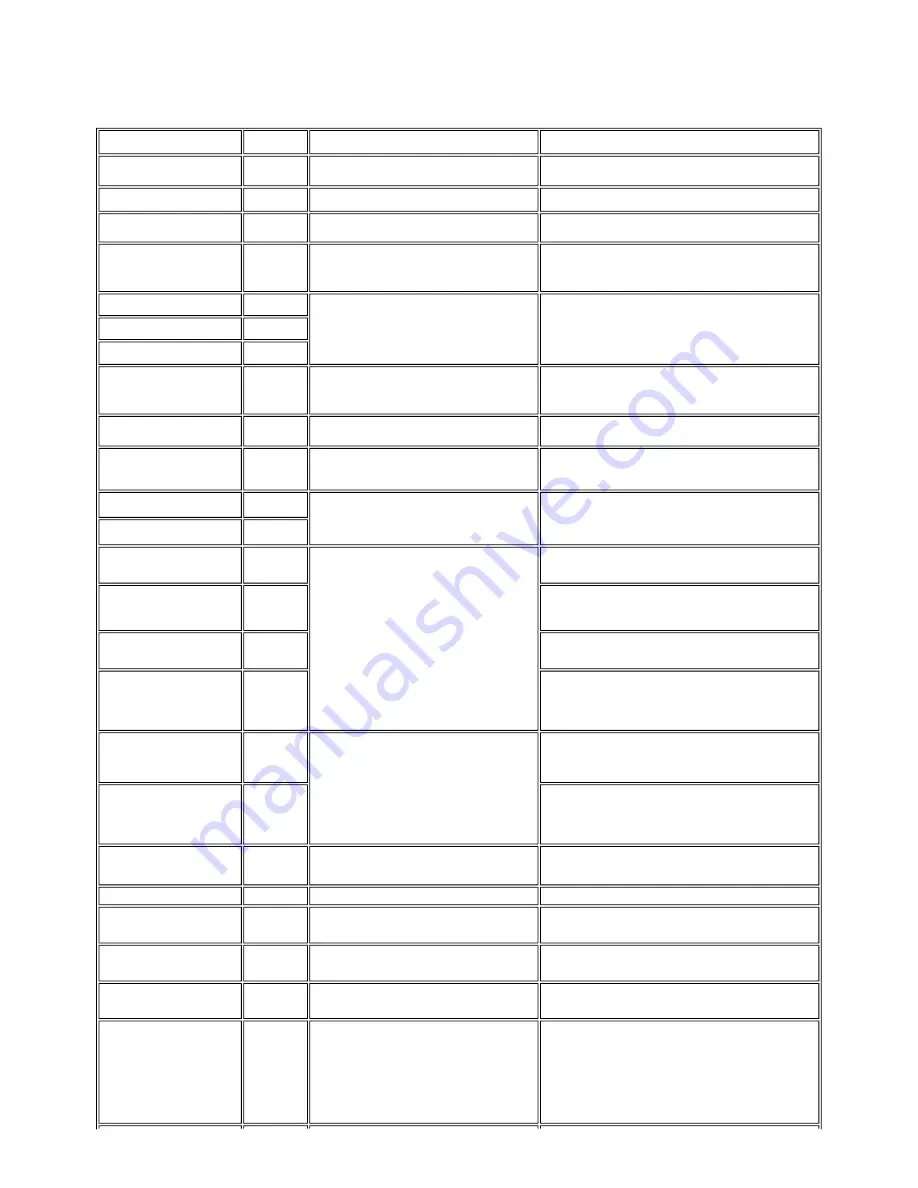

2-1. Operator Call Errors (by Alarm LED Blinking in Orange)

Error

Error code

Message on the LCD

Solution

No paper (ASF).

[1000]

Auto sheet feeder.

There is no paper. Load paper and press [OK].

Set the paper in the ASF, and press the OK button.

No CD / DVD tray.

*1

[1001]

There is no CD-R tray. Attach the tray and press [OK].

Set the CD / DVD tray, and press the OK button.

No paper in the front paper feed

cassette.

[1003]

Cassette.

There is no paper. Load paper and press [OK].

Set the paper in the cassette, and press the OK button.

No CD or DVD

*1

.

[1002]

Printable disc is not set. Correctly place a disc in the CD-R

tray and press [OK].

Set a CD or DVD in the CD / DVD tray (which is ejected at error

occurrence), and inset the CD / DVD tray in the proper position. Then,

press the OK button.

Paper jam.

[1300]

The paper is jammed. Clear the paper and press [OK].

Remove the jammed paper, and press the OK button.

Paper jam in the rear guide.

[1303]

Paper jam in the under guide.

[1304]

No ink.

[1600]

Ink has run out. Replace the ink tank and close the cover.

(U041)

Replace the empty ink tank(s) and close the cover. When pressing the

OK button, printing can be continued though ink may run out during

printing..

Ink tank not installed.

[1660]

The following ink tank cannot be recognized. Applicable

ink color (U043)

Install the applicable ink tank(s) properly, and confirm that the LED's of

all the ink tanks light red.

The print head is not installed or it

is not properly installed.

[1401]

Print head is not installed. Install the print head.

Install the print head properly.

The print head temperature sensor

error

[1403]

Error code

Handle this error by turning ON/OFF the machine. If not recovered, the

print head may have problems. Replace the print head.

Faulty EEPROM data of the print

head

[1405]

Inner cover open before printing on

paper.

(print

continuable).

[1841]

*2

Inner cover is open. Close the inner cover and press [OK].

Close the inner cover, and press the OK button.

Inner cover open during printing on

paper.

(print NOT

continuable).

[1846]

*2

Close the inner cover, and press the OK button to clear the error. The

paper being printed at error occurrence will be ejected without printing

the remaining data for the ejected paper, then printing will resume from

the next page.

Inner cover open during printing on

paper (print continuable).

(print

continuable).

[1851]

*1

Close the inner cover, and press the OK button.

Inner cover open during printing on

paper

(print NOT

continuable).

[1856]

*1

Close the inner cover, and press the OK button to clear the error. The

paper being printed at error occurrence will be ejected without printing

the remaining data for the ejected paper, then printing will resume from

the next page.

Inner cover closed during CD /

DVD printing

(print

continuable).

[1850]

*1

Open the inner cover, place the CD-R tray and press [OK]. Open the inner cover which functions as the CD / DVD tray feeder, set

the CD / DVD tray in the feeder, and press the OK button.

Inner cover closed during CD /

DVD printing

(print NOT

continuable).

[1855]

*1

Open the inner cover, and press the OK button to clear the error. The

CD or DVD being printed at error occurrence will be ejected without

printing the remaining data for the ejected CD or DVD, then the next

print job will be done.

Multiple ink tanks of the same color

installed.

[1681]

More than one ink tank of the following color is installed.

(U075)

Replace the wrong ink tank(s) with the correct one(s).

Ink tank in a wrong position.

[1680]

Some ink tanks are not installed in place. (U072)

Install the ink tank(s) in the correct position.

Warning: The waste ink absorber

becomes almost full.

[1700]

The waste ink absorber is almost full. Press [OK] to

continue but early replacement recommended. <See

manual>

Press the OK button. The waste ink absorber full error (service call

error) may occur soon.

The connected digital camera or

digital video camera does not

support Camera Direct Printing.

[2001]

Incompatible device detected. Remove the device.

Remove the cable between the camera and the machine.

Automatic duplex printing cannot

be performed.

[1310]

This paper is not compatible with duplex printing. Remove

the paper and press [OK].

Press the OK button to eject the paper being used at error occurrence.

Printing will resume from on the front side of the next page. Te data of

the back of the page in printing when the error occurred is not printed.

Failed in automatic print head

alignment.

[2500]

Auto head align has failed. Press [OK] and repeat

operation. <See manual>

Press the OK button.

- If paper is being fed at error occurrence, the error is indicated after the

paper is ejected.

- If the error occurs, the print head alignment values are not changed.

- After exit from the error by the OK button, the automatic print head

alignment will not be re-done.

When printing was not possible due to no ink or no ink ejection.

or, the AD value of the sensor was incorrect.

1-5

Summary of Contents for PIXMA MP950

Page 5: ...Part 1 MAINTENANCE ...

Page 9: ...To the table of contents To the top Part 1 1 MAINTENANCE 1 4 ...

Page 15: ...To the table of contents To the top Part 1 2 LIST OF ERROR DISPLAY INDICATION 1 10 ...

Page 40: ...Part 2 TECHNICAL REFERENCE ...

Page 47: ...3 7 Copying 4 SCANNING 2 7 ...

Page 48: ...To the table of contents To the top Part 2 3 PRINT MODE 2 8 ...

Page 52: ...Part 3 APPENDIX ...