(2) Periodic maintenance

No periodic maintenance is necessary.

(3) Periodic replacement parts

There are no parts in this machine that require periodic replacement by a service engineer.

(4) Replacement consumables

There are no consumables that require replacement by a service engineer.

1-2. Customer Maintenance

1-3. Product Life

(1) Machine

Specified print volume (I) or the years of use (II), whichever comes first.

(I) Print volume: 24,000 pages

(II) Years of use: 5 years of use

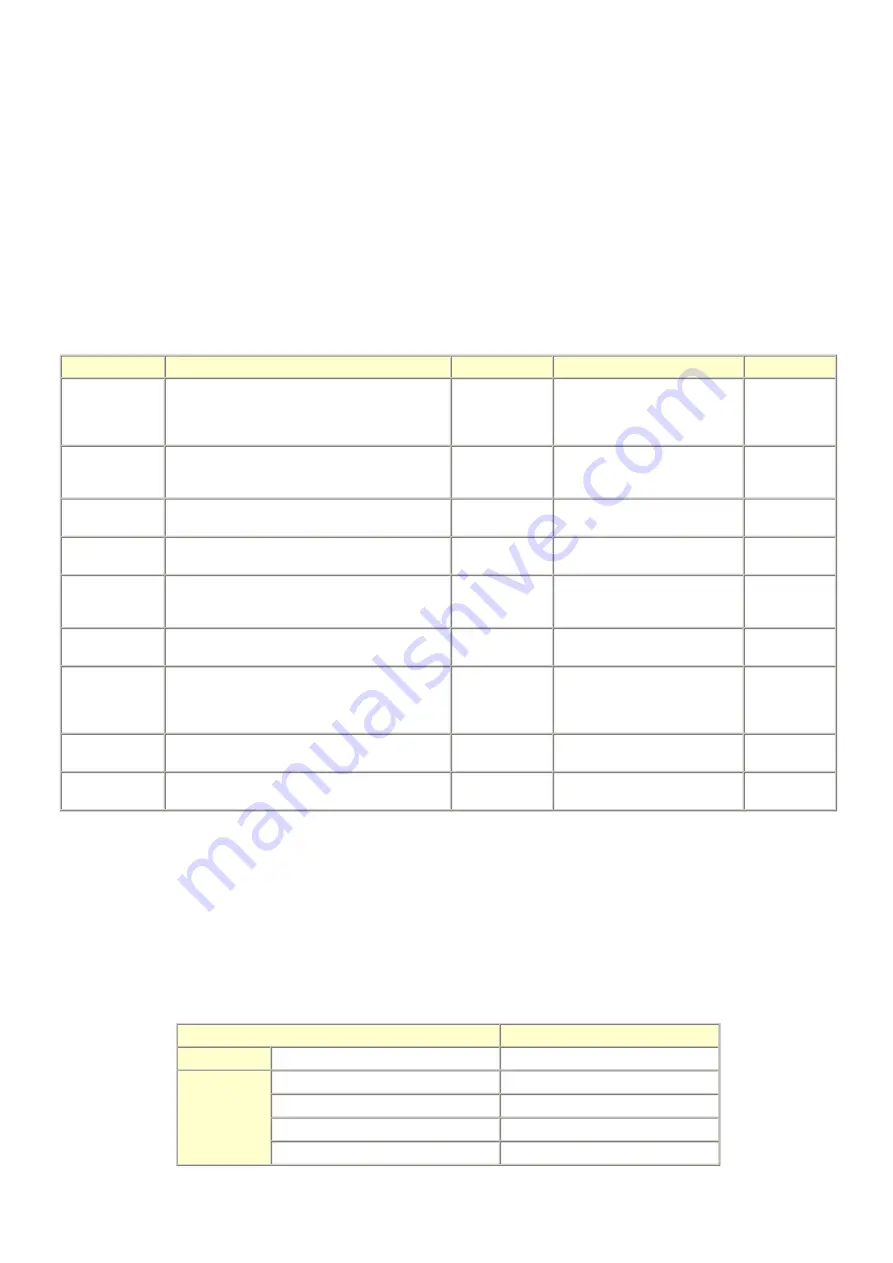

Adjustment

Timing

Purpose

Tool

Approx. time

Automatic print

head alignment

- At print head replacement

- When print quality is not satisfying (uneven printing,

etc.)

To ensure accurate

dot placement.

- Machine buttons

- Matte Photo Paper (MP-101) for the

MP810

- Computer (MP driver)

MP810: 13 min.

(Use MP-101.)

MP960: 6 min.

Manual print head

alignment

- At print head replacement

- When print quality is not satisfying (uneven printing,

etc.)

To ensure accurate

dot placement.

- Machine buttons

- Computer (MP driver)

MP810: 15 min.

MP960: 6 min.

Print head cleaning

When print quality is not satisfying.

To improve nozzle

conditions.

- Machine buttons

- Computer (MP driver)

1 min.

Print head deep

cleaning

When print quality is not satisfying, and not improved by

print head cleaning.

To improve nozzle

conditions.

- Machine buttons

- Computer (MP driver)

2 min.

Ink tank

replacement

When an ink tank becomes empty. ("No ink error"

displayed on the monitor or on the machine LCD, or

short flashing of an ink tank LED)

---

---

1 min.

ASF paper feed

roller cleaning

- When paper does not feed properly.

- When the front side of the paper is smeared.

To clean the paper

feed rollers.

- Machine buttons

- Computer (MP driver)

2 min.

ASF sub- roller

cleaning

When the paper fed from the ASF is smeared due to ink

mist attached to the ASF sub-rollers.

To clean the ASF

sub-rollers.

- Machine buttons

See Part 2, 4. FAQ, How to make and

set the ASF sub-roller cleaning sheet,

for details.

1 min.

Bottom plate

cleaning

When the back side of the paper is smeared.

To clean the platen

ribs.

- Machine buttons

- Computer (MP driver)

1 min.

Scanning area

cleaning

When the platen glass or document pressure plate sheet is

dirty.

To clean the platen

glass.

Soft, dry, and clean lint-free cloth.

1 min.

MP810 / MP960

Black

1500 character pattern

11,000 pages

Color

7.5% duty per color pattern

7,200 pages

A4, photo, borderless printing

500 pages

4 x 6, photo, borderless printing

4,300 pages

Postcard, photo, borderless printing

1,000 pages

1-2