(20/21)

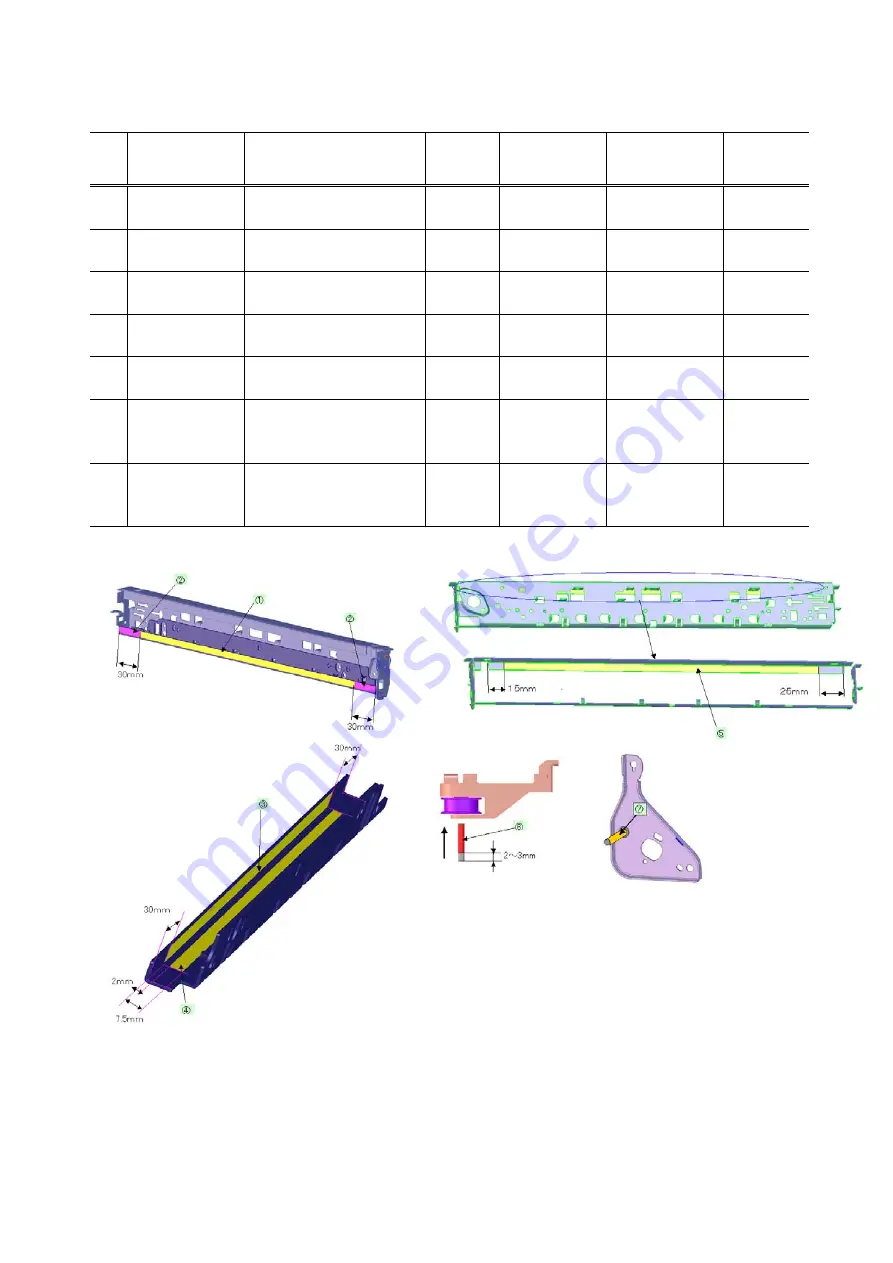

2-4. Grease

application

No Part

name

Where to apply grease /

oil

Drawing

No.

Grease

Grease

amount (mg)

Number of

drops x

locations

1 Carriage

rail

The surface where the

carriage unit slides

(1)

Floil KG107A

270 to 330

---

2 Carriage

rail

The surface where the

carriage unit slides

(2)

Floil KG107A

18 to 36

1 x 2

3 Carriage

rail

The surface where the

carriage unit slides

(3)

Floil KG107A

360 to 440

---

4 Carriage

rail

The surface where the

carriage unit slides

(4)

Floil KG107A

360 to 440

---

5 Main

chassis

The surface where the

carriage unit slides

(5)

Floil KG107A

230 to 290

---

6 Parallel

pin

The pin surface which

contacts the idler pulley

hole

(6)

Floil KG107A

9 to 18

1 x 1

7

APP code wheel

gear shaft

APP code wheel gear

sliding portion (the entire

surface)

(7)

Floil KG107A

9 to 18

1 x 1

1 drop = 9 to18 mg