( 15 /21)

(8-1. FAQ (Problems specific to the iP1000 and corrective actions) cont’d)

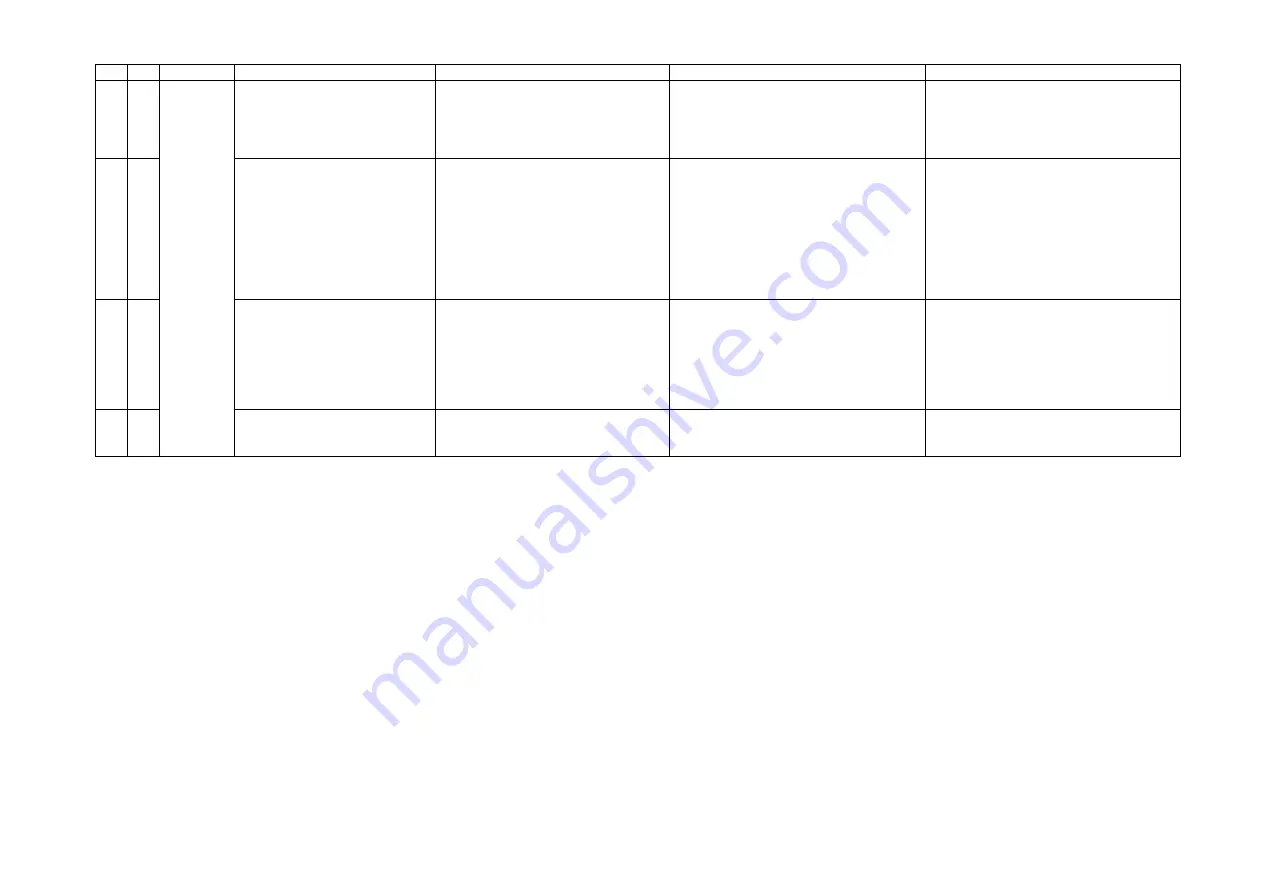

No.

*

Function

Phenomenon

Possible Call / Claim

Corrective action

Cause

8

B

Smearing on printed side.

- Smear on the printed side of paper

- Cannot print properly

- Paper edge crease

1. Correct the paper curl.

2. Recommend the user to conduct

printing in the print quality assurance

area. (In the iP1500, the head-to-paper

distance cannot be changed.)

The edge of paper rises due when paper

is curled, causing the print head to rub

against the printed surface of paper,

resulting in smearing.

9

B

Smearing on the backside, or

address side of postcards

<Photo Paper Plus Double Sided>

- Smears on the already printed side

when printing the other side

<When printing the address side of

postcards>

- Smears on the address side

<When printing the message side of

postcards>

- Smears on the backside

1. Perform Bottom Plate cleaning from

the printer driver.

2. Clean the ribs on the platen with cotton

swabs/buds.

When borderless printing is conducted

continuously, ink mist attaches to the ribs

on the platen, and is transferred to the

backside of the following paper.

10

C

Horizontal lines or uneven print

density at the trailing edge of

paper

- Cannot print to the bottom edge of

paper

- Lines or uneven print density appear

in the trailing edge of paper

- Cannot print properly

1. Recommend printing in the print quality

assurance area.

2. Change the print quality from standard

to high mode.

3. Try other paper (PP-101)

When the paper end comes off the pinch

roller, printing is performed without the

paper being held, preventing the ink drops

from being ejected in the correct

positions, resulting in unevenness.

Note: The problem is less noticeable than

that of the i320.

11 C

Image

quality

Horizontal lines or uneven print

density due to LF roller feeding at

small pitch

- Lines or uneven print density (on skin

tones and background)

- Cannot print properly

Change the print quality from standard to

high mode.

As the print media slightly slips while

being fed by the LF roller, printed areas

overlap, causing the problem.

*Occurrence level:

A: The phenomenon is likely to occur frequently. (Caution required).

B: The phenomenon may occur under certain conditions, but likeliness is assumed very low in practical usage.

C: The phenomenon is unlikely to be recognized by the user, and no practical issues are assumed.