5

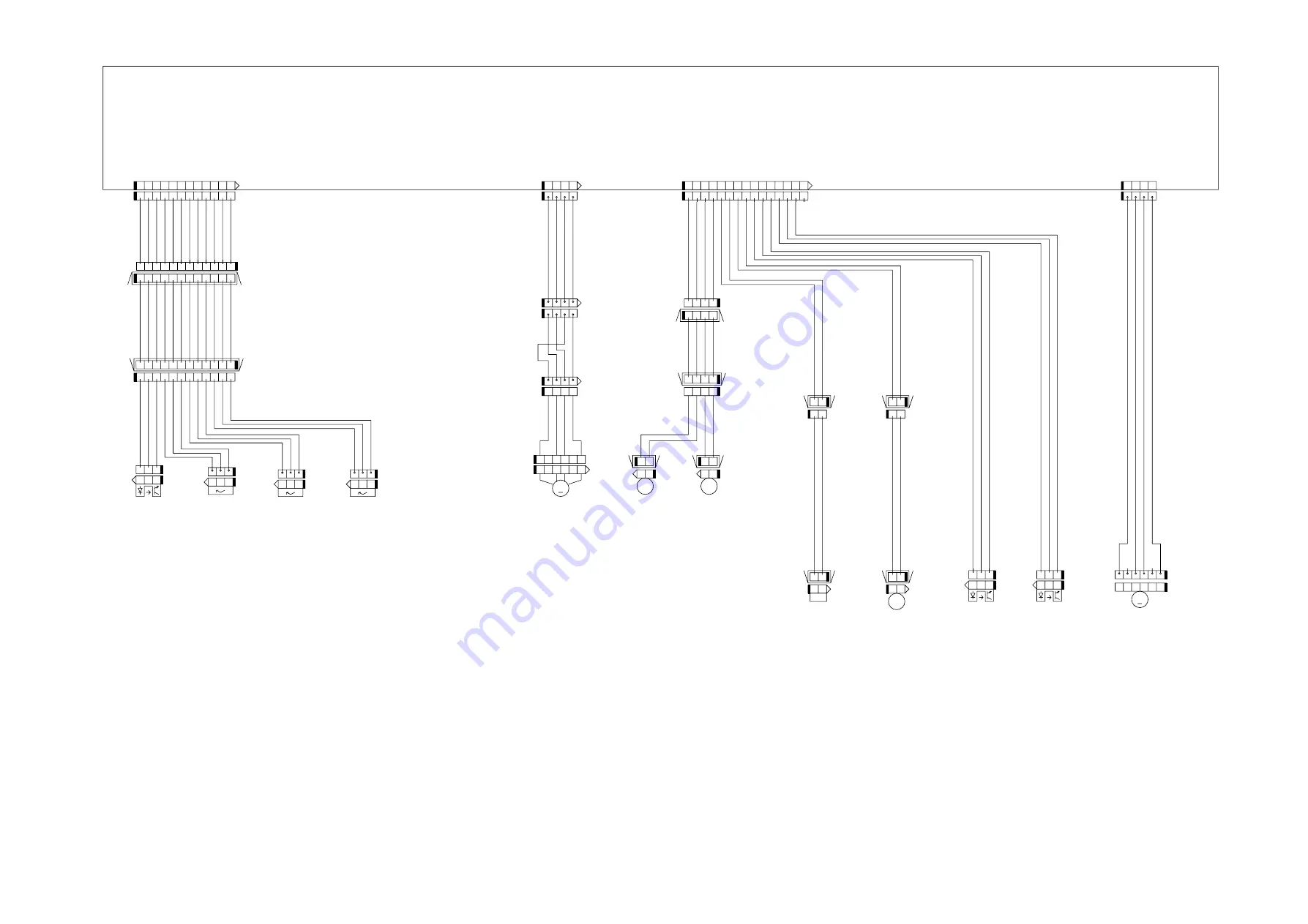

General Circuit Diagram (5/7)

F-1-5

2

1

2

3

4

5

6

1

2

3

4

5

6

M

1

2

1

CL

2

1

CL

C2

C3

M3

RGV8(SNS3V)

GND

1

2

3

P

1

1

1

2

3

4

5

6

7

8

9

10

11

12

RGV19(VM_26V_2)

RGV19(VM_26V_2)

RGV19(VM_26V_2)

RGV7(SNS5V2)

2

1

CL

M

2

3

S

2

1

SL

1

2

3

2

3

P

S

2

3

P

S

1

2

3

SR3

SP1

SR4

M2

PICKUP_ATUKAIJO__SNS_1*

KYUUSHI_SNS_F*

YOUSHIHABA_SNS*

GND

OUT_LFNIP_B

OUT_LFNIP_AB

UT_LFNIP_A

J3902

RGV7(SNS5V2)

GND

OUT_LFNIP_BB

PICKUP_CL_OUT

KYUUSHI_CL_OUT

FLAPPER_SOL_OUT

PINCH_CL_OUT

RGV8(SNS3V)

GND

S1

SR2

RGV8(SNS3V)

RGV19(VM_26V_2)

1

GND

KYUUSHI_SNS_R1*

RGV7(SNS5V2)

GND

J3801

J3901

PINCH_OPEN_SNS*

PINCH_CLOSE_SNS*

J4003

C1

SP14

SP13

OUT_ZENMENM_B

OUT_ZENMENM_A

OUT_ZENMENM_AB

OUT_ZENMENM_BB

2

1

J3916H

J3915DH

1

2

3

J3919

1

2

3

J3917

1

2

J3916

12 11 10 9

8

2

3

4

5

6

1

7

J3816D

12

11

10

9

8

2

3

4

5

6

1

7

J3811L

1

2

3

4

J3910L

1

2

3

4

1

2

3

4

J3911D

J3911DH

2

3

4

1

J4031L

2

3

4

1

2

3

4

1

J4032D

2

3

4

1

J4031D

J3910LH

1

2

3

4

J3910D

J3816DH

J3811LH

J3914H

1

2

J3914

15

14

13

12

11

10

9

8

2

3

4

5

6

1

7

15

14

13

12

11

10

9

8

2

3

4

5

6

1

7

12 11 10 9

8

2

3

4

5

6

1

7

J3811D

2

3

4

1

2

3

4

1

12

11

10

9

8

2

3

4

5

6

1

7

2

3

1

J3815

2

3

1

J3814

2

3

1

J3813

3

4

5

6

1

2

3

4

5

6

1

2

J3921

1

2

J3918L

J3918DH

1

2

J3918D

1

2

J3915L

1

2

J3915D

1

2

3

J3812

2

3

4

1

2

3

4

1

12

11

10

9

8

2

3

4

5

6

1

7

J3816L

Main controller PCB (5/7)

Roll media

pick-up

cam sensor

Roll media

pick-up motor

Roll media

pick-up cam

clutch

Roll media

pick-up

roller

clutch

Flapper

solenoid

Pinch roller

pressure

clutch

Pinch roller

releace

detection

sensor

Pinch roller

pressure

detection

sensor

Pinch roller

pressure

motor

Roll media

detection

sensor

Roll media

pick-up roller

paper

detection

sensor

Roll media

width detection

sensor

Summary of Contents for imagePROGRAF iPF815

Page 2: ......

Page 6: ......

Page 11: ...Chapter 1 PRODUCT DESCRIPTION...

Page 12: ......

Page 14: ......

Page 74: ......

Page 75: ...Chapter 2 TECHNICAL REFERENCE...

Page 76: ......

Page 86: ...Chapter 2 2 8 Printing Modes...

Page 87: ...Chapter 2 2 9...

Page 129: ...Chapter 3 INSTALLATION...

Page 130: ......

Page 132: ......

Page 146: ...Chapter 3 3 14...

Page 147: ...Chapter 4 DISASSEMBLY REASSEMBLY...

Page 148: ......

Page 150: ......

Page 207: ......

Page 208: ......

Page 209: ...Chapter 5 MAINTENANCE...

Page 210: ......

Page 212: ......

Page 216: ...Chapter 5 5 4 5 Close upper cover 1 F 5 6 1...

Page 217: ...Chapter 5 5 5...

Page 218: ......

Page 219: ...Chapter 6 TROUBLESHOOTING...

Page 220: ......

Page 222: ......

Page 249: ...Chapter 7 SERVICE MODE...

Page 250: ......

Page 252: ......

Page 273: ...Chapter 7 7 21...

Page 274: ......

Page 275: ...Chapter 8 ERROR CODE...

Page 276: ......

Page 278: ......

Page 313: ...Appendix...

Page 314: ......

Page 322: ......

Page 323: ...Feb 27 2017...

Page 324: ......