CHAPTER 5 TROUBLESHOOTING

5-2

COPYRIGHT © 1999 CANON INC.

CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

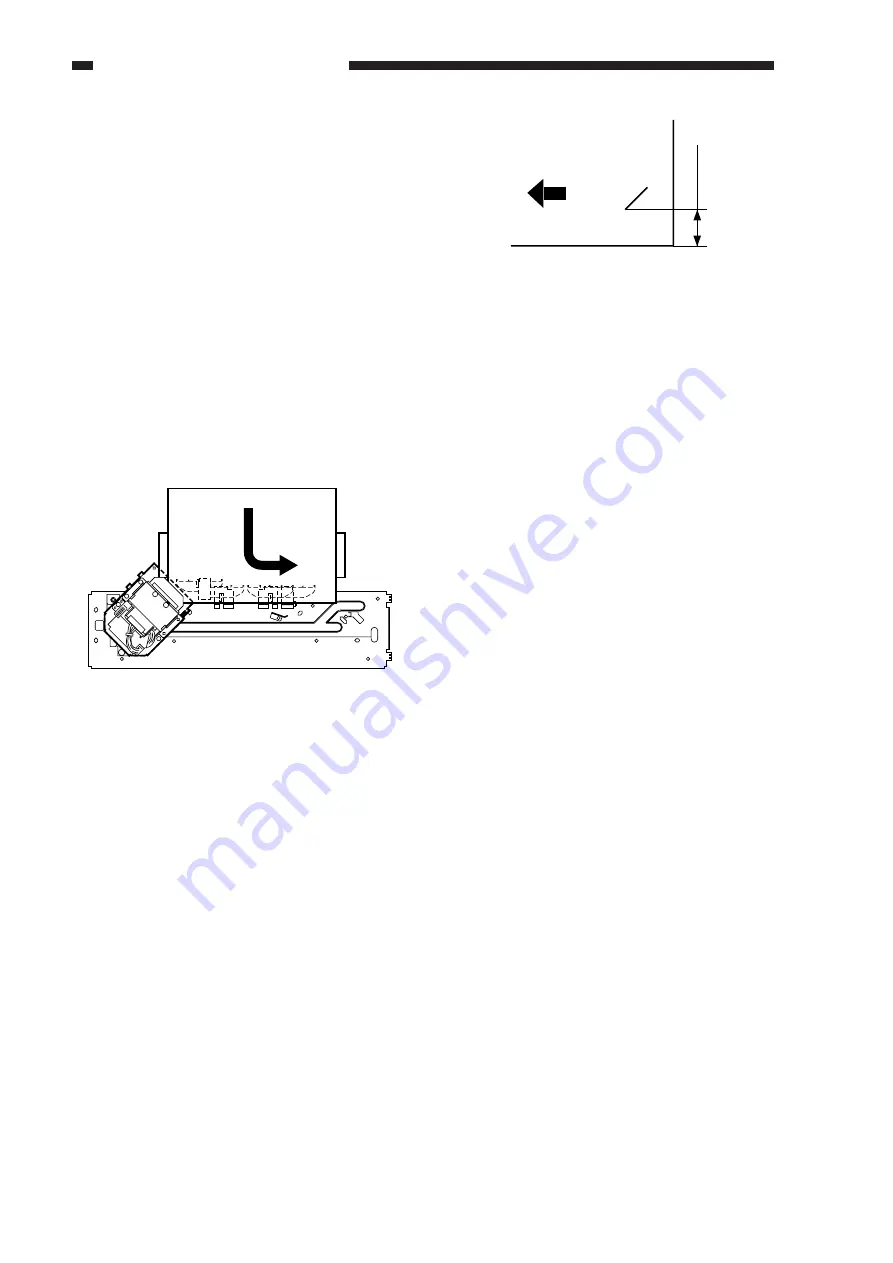

5 ±2 mm

Direction of delivery

Figure 5-104

6) Press SW104 once so that you may enter a

new adjustment value.

• The stapler will return to the home posi-

tion once, and then will return to the sta-

pling position. LED101 will indicate the

present value.

7) Based on the result of a check, press

SW105 or SW106 on the finisher control-

ler PCB.

• A single press on SW105 moves the sta-

pling position to the front by about 0.35

mm. LED101 indication, on the other

hand, will increment by '1' in the positive

(+) direction.

• A single press SW106 moves the stapling

direction to the rear by about 0.35 mm.

LED101, on the other hand, will incre-

ment by '1' in the negative (-) direction.

8) Insert a stack of several A4 or LTR sheets

into the processing tray as in step 3).

9) Press SW104 so that the new adjustment

value is stored.

• Stapling occurs automatically so that you

can check the stapling position. LED 101

will indicate '0'.

10) Turn off the power.

11) Shift all bits of SW103 to OFF.

12) Turn on the power, and move down the

swing guide.

2) Press SW104 on the finisher controller

PCB.

• The swing guide of the machine will open

and, at the same time, the front jogging

plate and the rear jogging plate will move

to the home position. Thereafter, the front

jogging plate and the rear jogging plate

will move to the front 1-point stapling po-

sition.

At the same time, the stapler moves to the

front 1-point stapling position. Further,

LED101 on the finisher controller PCB

will indicate the present value, which is

between '-12' and '14'.

3) Insert a stack of A4 or LTR sheets into the

processing tray. At this time, butt the rear

edge of the stack against the rear jogging

plate.

Figure 5-103

• If the gap between the front jogging plate

and the front edge of the stack is 1 mm or

more, turn off the power; then, shift all

bits of SW103 to OFF, and stop the ad-

justment work. Adjust the alignment

width once again, and start the adjustment

of the stapling position.

4) Press SW104 on the finisher controller

PCB.

• The stapler will staple the stack, and

LED101 will indicate '0'.

5) Remove the stack, and check the position

of the staple against the standard. If the

position is correct, end the adjustment

work, i.e., turn off the power, shift all bits

of SW103 to OFF, and then turn on the

power once again.

If you need to adjust the stapling position,

go to the next step.