CHAPTER 1

1 - 8

COPYRIGHT

2002 CANON INC. CANOSCAN 8000F REV.0 OCT. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

q

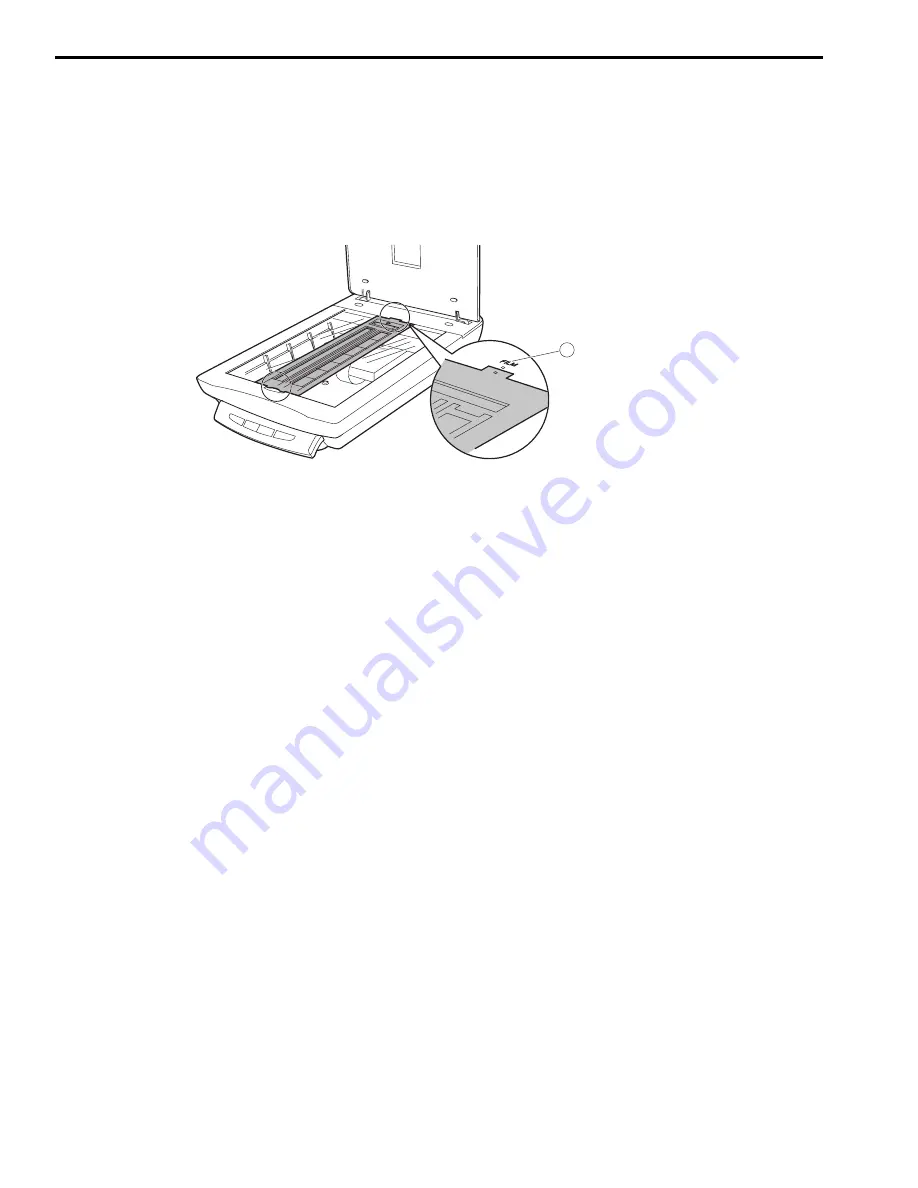

FILM Mark

3) Place the loaded film guide by aligning its leading tab with FILM mark on the document

glass and close the document cover.

Figure 1-9

4) Send the scan command from the host computer.

1