CAMON C500 Stump Grinder

CAMON C500 Stump Grinder

CAMON-C500/11.11/4

CAMON-C500/11.11/5

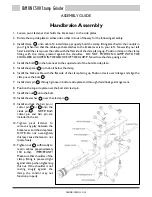

Handbrake Assembly

1. Loosen pivot fastener that holds the brake lever to the side plates.

2. Rotate the top side plate to either side so that it is out of the way for the following assembly.

3. Install clamp onto cable. To install clamp properly, hold the clamp fitting attached to the conduit in

your right hand so that the cable eye that attaches to the brake lever is to your left. Now with your left

hand install the clamp over the cable with the flat side of the clamp facing up. Position clamp on the clamp

fitting with the clamp pressed against the shoulder. DO NOT POSITION CLAMP WITH THE

SHOULDER LOCATED IN THE GROOVE OF THE CLAMP. Now close the clamp using a vice.

4. Install the bolt in the hole next to the squared end of the bottom side plate.

5. Install the spacer on the bolt below the clamp.

6. Install the brake cable with the flat side of the clamp facing up. Position clevis over linkage and align the

clamp over the bolt .

7. Install clevis pin through groove in bottom side plate and through clevis/linkage arrangement.

8. Position the top side plate over the bolt and clevis pin.

9. Install the nut onto the bolt.

10. Install the washer over the clevis pin .

11. Install and lock the hair pin or

cotter pin or onto the

clevis pin . NOTE: Both

cotter pin and hair pin are

included in the kit.

12. Tighten pivot fastener to

remove any play between the

brake lever and the side plates.

NOTE: Do not over-tighten,

this may cause the lever to not

rotate freely.

13. Tighten nut sufficiently to

retain cables (approximately

150 in-Ibs). IMPORTANT!

Make sure that shoulder of the

clamp fitting is pressed tight

against clamp when tightening

this nut. If the shoulder is not

resting snugly against the

clamp, the control may not

function properly.

ASSEMBLY GUIDE

OPERATION

WARNING!

!

Operation

Before operating, please consult the SAFETY section for vital information relating to the

operation of this powerful machine.

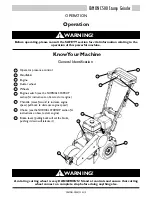

Know Your Machine

General Identification

WARNING!

!

A rotating cutting wheel is very DANGEROUS! Stand at controls and ensure that cutting

wheel comes to a complete stop before doing anything else.

1

2

7

8

9

3

6

5

4

Operator presence control

Handlebar

Engine

Cutter wheel

Wheels

Engine switch

(see the NORMAL START-UP

section for instructions on how to start engine)

Throttle

(move forward to increase engine

speed, pull back to decrease engine speed)

Choke

(see the NORMAL START-UP section for

instructions on how to start engine)

Brake lever

(pulling back will set the brake,

pushing it down will release it)

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

7

6

6

1