TOV

Installation, Operation and Maintenance Manual

13

WKM-TOV-IOM

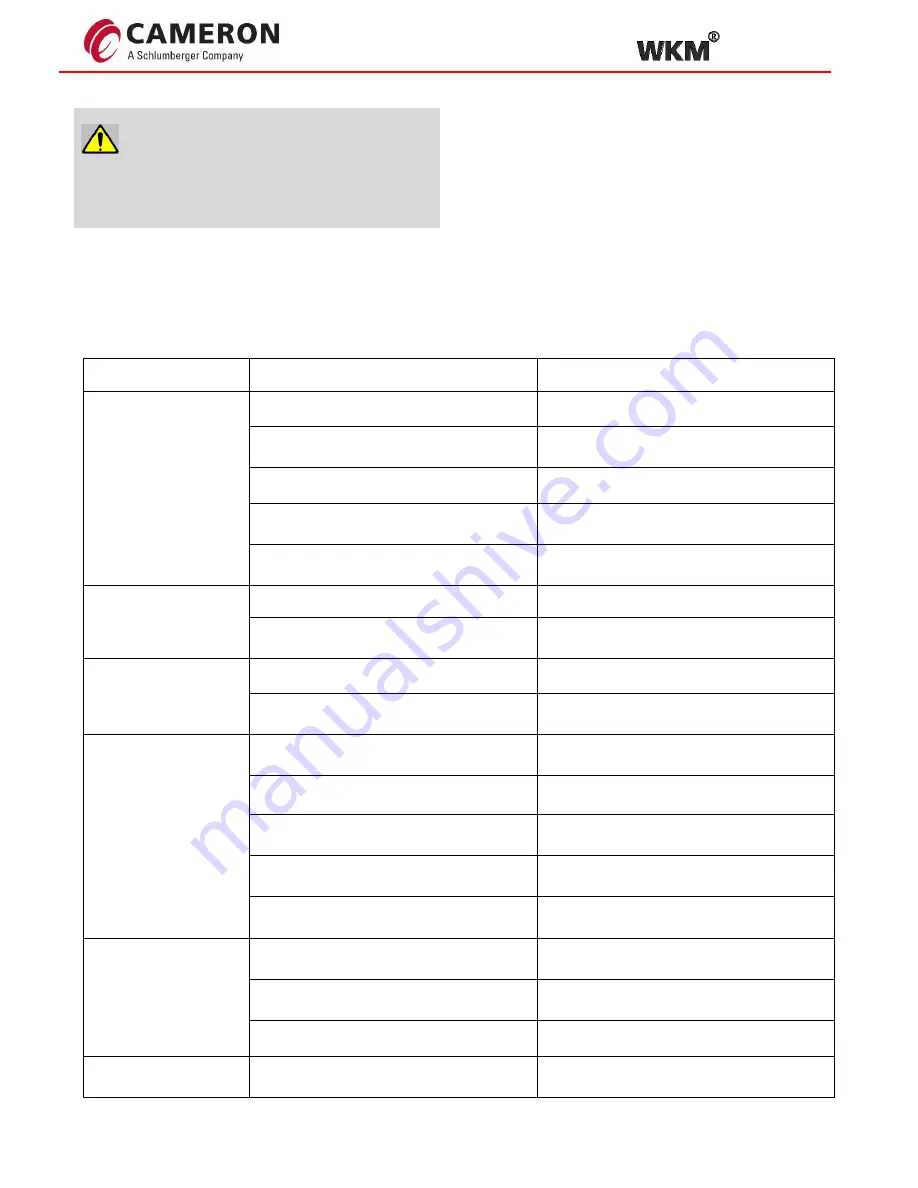

Troubleshooting guide

Symptom

Possible Cause

Resolution

Valve does not seal

properly

1. Valve not fully closed.

1. Close valve.

2. Foreign matter is present between seat

and disc.

2. Operate several times to wipe clean.

3. Operator stops are not set properly.

3. Adjust stops to proper setting.

4. The seat and/ or disc is worn or

damaged.

4. Replace worn parts.

5. Seat retainer screws are not tight.

6. Tighten seat retainer screws as per

torquing method.

Valve is leaking around

the stem

1. Packing retainer flange nuts too loose.

1. Tighten packing nuts.

2. Packing damaged.

2. Replace packing -

See “Packing

maintenance”.

Bottom cap gasket

leaking

1. Bottom cap bolting loose.

1. Tighten bottom cap bolting.

2. Spiral wound gasket damage.

2. Replace spiral wound gasket

– See

“Bottom cap gasket maintenance”.

Valve is hard to rotate

1. Shaft packing too tight.

1. Tighten packing only sufficiently to stop

leaks.

2. Operator failed/ not installed properly.

2. Replace or repair.

3. Build up of solids or roughness on edge

of disc.

3. Operate several times to wipe clean or

disassemble valve and clean disc edge.

4. Shaft key has sheared.

4. Determine cause of shearing and

correctly replace shaft key.

5. Fluid solidification between bearings

and shaft.

5. Flush bearings.

Jerky operation

1. Packing is too tight.

1. Loosen packing nuts, cycle valve,

retighten.

2. Air supply inadequate for the actuator.

2. Increase air supply pressure and/or

volume.

3. Actuator/shaft adapter misaligned.

3. Remove actuator mounting and realign.

The valve will not open

1. Disc hits on side of pipe.

1. Check for proper pipe clearance.

Routine maintenance

Caution:

The line shall be depressurized before starting any

maintenance. Failure to do so may cause serious

personal injury and or equipment damage.

Because of the simple design and operation, WKM

®

Triple Offset Valves require virtually no maintenance.

Its non-lubricated construction provides reliable leak free

performance without routine servicing.

The only preventative maintenance recommended for

the valve is to periodically inspect for leaks around the

shaft packing. Should a leak appear, the packing can be

adjusted by tightening the packing retainer nuts slightly.

Avoid excessive tightening which may result in excessive

valve torque or premature packing wear.(Refer Chart B

for recommended retainer torque values)