p.

1111

- M

an

u

al

c

od

e:

F

A

0

1

2

8

3

-E

N

FA

0

1

2

8

3

-E

N

v.

11

- 1

1/

2

0

18 - © C

am

e S

.p.

A

. - T

h

e m

an

u

al

's c

onte

nts m

ay b

e e

d

ite

d at a

ny ti

m

e w

ith

ou

t n

oti

ce

.

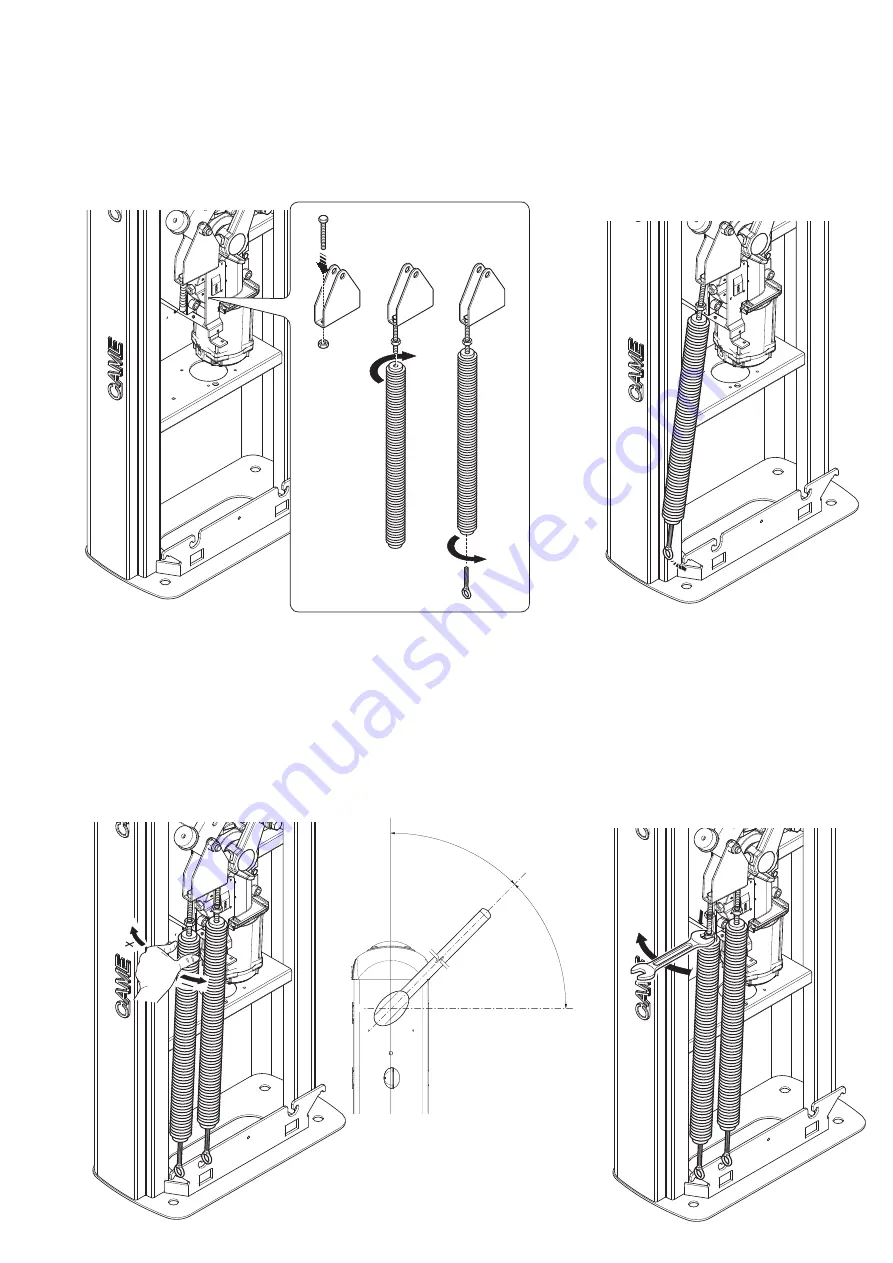

Release the gearmotor and manually turn the spring to increase or decrease tautness. The spring should stabilize at 45°.

Fasten the counter nut and lock the gearmotor again.

Check the proper working state of the spring.

With the boom raised vertically the spring is not taut.

With the boom lowered horizontally the spring is taut.

Release the gearmotor and position the boom vertically. Lock the gearmotor again.

Install the spring into the barrier in the following way:

- fit a UNI5739 M12x70 screw into the attachment bracket and tighten the UNI5588 M12 nut to the screw

.

- tighten the screw into the spring

;

- tighten

the eyelet tie rod below the spring

.

Hook the tie rod to the anchoring bracket.

Perform the same procedure for a possible second spring.