Shut down procedure

Initial setup and operation of your new pressure washer, cont.

The pressure was set at the factory during the testing procedure, no adjustments to the machine

should be required for operation. During operation the burner may cycle on and off. The

adjustable thermostat may be set to desired temperature. Water temperature will not exceed 190

degrees, the safety switches will shut the burner down.

During operation do not leave the

machine running for more than two minutes without the trigger gun being pulled.

Although your machine has a by-pass valve on it and may have a thermal relief system, this can

cause extensive pump damage.

If machine will not be discharging water for more than

two minutes, shut the machine off.

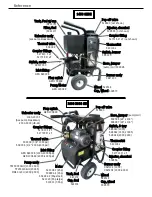

Your machine is supplied with interchangeable spray tips. The colored tips are for high-pres-

sure rinse at different spray angles. The red tip sprays at zero degrees; yellow, fifteen degrees;

green, twenty-five degrees; and white, forty degrees. The yellow tip is used for most standard

applications.

Be sure the quick coupler is fully engaged before pulling the trigger

gun.

Failure to do so may result in the tip becoming a projectile and may be lost and damage

to property and persons may occur.

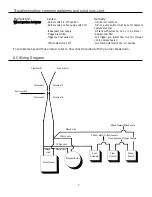

Your pressure washer is supplied with a downstream chemical injector. The 1/4” clear vinyl

tube is to be inserted into the desired chemical to apply. The chemical injector will only open

up and allow chemical into the line when the forward handle (see wand breakdown page 10) on

the wand is turned counter clock wise.This enables the pressure to drop to approximately 250

PSI and draw chemical, this is a valve that allows the water to flow through the wand and

through the chemical tip. The rate of injection can also be set by turning the knob that the

clear vinyl tube attaches to.

Be sure to flush injection system with clear water after use.

If an accurate injection rate is desired, use this formula.

(GPM x 128) / ounces drawn in one minute = x: 1

IE: If a 2.0 GPM machine draws eight ounces of chemical in one minute: 2 x 128

8

= 32:1

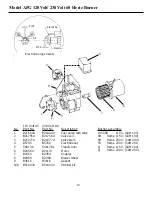

1. Turn off the power switch on the burner. Continue to run the pressure washer and pull

the trigger to circulate water through to cool the coil.

2. After several minutes when water is cool, shut off the pressure washer motor.

3. Shut off water supply and disconnect garden hose.

4. Be sure to double check for water leaks or oil leaks that should be repaired before the next

operation.

If you are going to store the machine for extended period of times in cold climates be sure to

winterize the equipment. A fifty percent anti-freeze solution may be drawn in through the inlet

of the pump using a short remnant of garden hose. This fluid should be run through the pump

and coil. When the fluid is discharged from the coil discharge your machine is winterized.

Do

not allow machine to freeze.

The pump oil should be changed after the first fifty hours of operation, then every year for

average service or more frequently for extensive use or hostile environments (dusty or high

moisture).

During

operation

Interchange-

able tips

Chemical

injector use

Calibration

Storage

Winter

storage

Pump

5