21

C

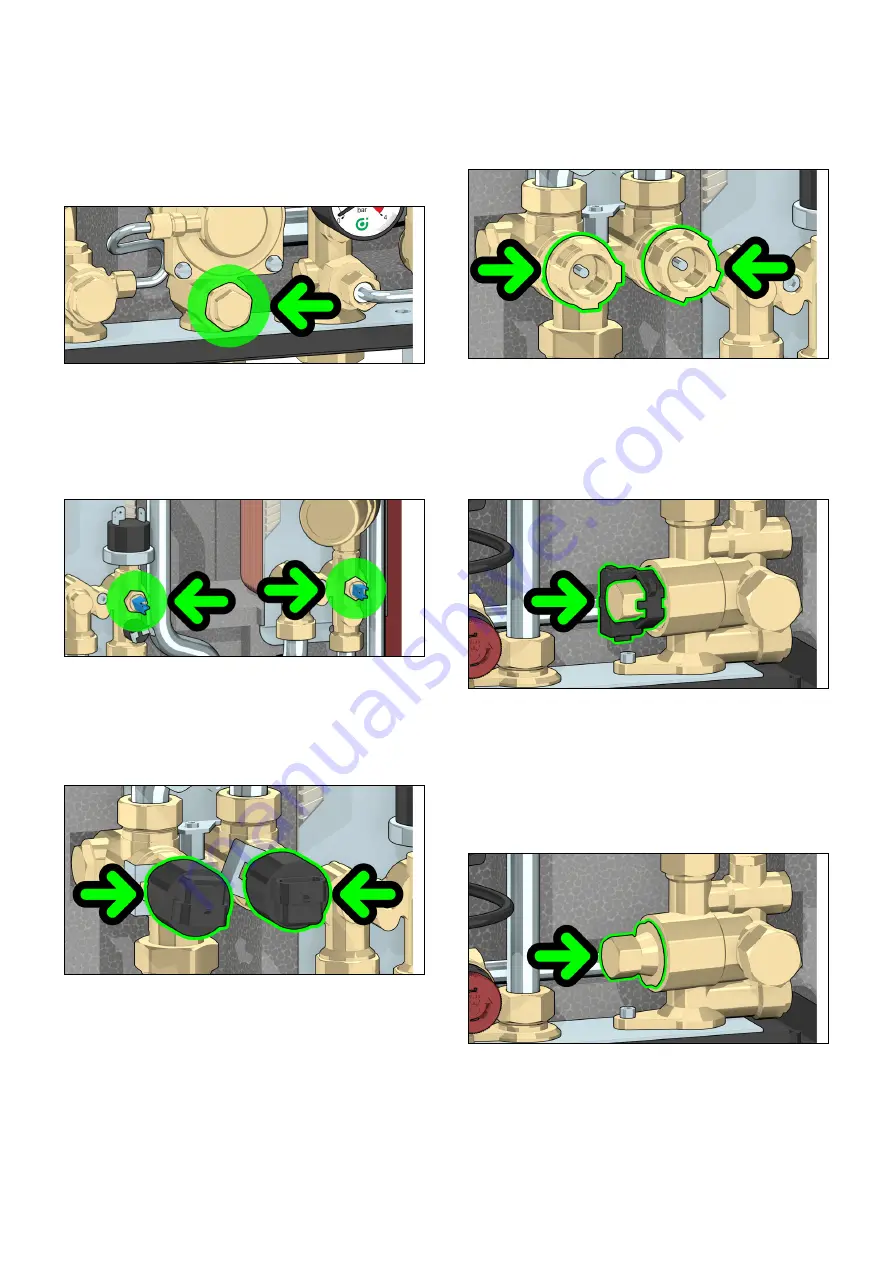

B

H

C

D

E

F

G

Cleaning the HIU primary circuit strainer

All heat interface units have a strainer on the inlet for water from the

centralised system.

To clean these strainers, carry out the following maintenance

procedure:

- Unscrew the cap (B)

- Remove the strainer mesh and discard any impurities it contains

- Refit the strainer mesh

- Refit the cap and tighten it.

Temperature probe replacement

- Disconnect the probe cable by bending tab (C) slightly

and extracting the connector.

- Unscrew the probe

- Fit the new probe

- Reconnect the connector respecting the only possible way it can

be inserted.

Replacing the actuator

- Extract the fixing clip (D) and then the actuator

- Position the new actuator (E)

- Insert the fixing clip, respecting the correct direction

- Reconnect the connector.

Replacing the valve obturator

- Disconnect the valve actuator (see previous paragraph)

- Extract the obturator, unscrewing the locking nut (F)

- Replace the obturator, screw on the locking nut (F) and then fit the

actuator

- Insert the fixing clip, respecting the correct direction

- Reconnect the connector.

Replacing the DHW priority flow meter

- Disconnect the flow meter cable acting on the connector

- Extract the flow sensor (G)

- Position the new sensor

- Reconnect the connector respecting the only possible way it can

be inserted.

Replacing or cleaning the DHW priority flow meter turbine

- Extract the flow sensor

- Unscrew and remove the cartridge (H)

- Remove any impurities or change the cartridge if necessary

- Screw the cartridge back in

- Reposition the flow sensor

When carrying out maintenance on the electrical part, follow the

indications on page 19 for the connections.

After concluding maintenance, proceed with the filling and checking

operations described in the chapter “commissioning” (page 9) and fit

the cover.

If you require any information regarding spare parts, please contact

Caleffi spa.