13

2. Remove the plastic cap from the liquid and suction service

valve on the heat pump outdoor unit and assemble the

heating piston and piston cap supplied with the outdoor unit

as shown in Fig. 26.

*

A07407

Fig. 26 – Accurator (bypass type)

Metering Device Components

NOTE

:

The Teflon seal on the piston should point towards the

liquid service valve. The size of the factory supplied piston

might have to be adjusted for long line applications (over 80 ft

/24.4 m). Refer to the Residential Long Line Application Guide

for additional information.

3. Attach the flare end of the filter drier assembly to the piston

cap (see Fig. 25).

4. Connect the field supplied line set to the filter drier

assembly and to the suction valve.

5. Insulate any exposed areas between filter drier and liquid

valve.

COMPLETE OUTDOOR POWER AND

CONTROL WIRING

!

WARNING

Failure to follow this warning could result in personal injury or

death.

The unit cabinet must have an uninterrupted or unbroken

ground to minimize personal injury if an electrical fault should

occur. The ground may consist of electrical wire or metal

conduit when installed in accordance with existing electrical

codes.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Unit failure as a result of operation on improper line voltage or

excessive phase imbalance constitutes abuse and may cause

damage to electrical components. Such operation could void

any applicable manufacturer warranty.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before performing service or maintenance, be sure indoor

unit main power switch is turned OFF and indoor blower has

stopped.

Lock out and tag switch with a suitable warning label.

Power Wiring

NOTE

: The indoor and outdoor units are powered separately

1. Mount indoor and outdoor power disconnect. The units are

factory wired for the voltage shown on the unit nameplates.

The fused disconnect switch must be provided within sight of

the unit, readily accessible, but out of reach of children.

Provisions for locking the disconnect switch on the OFF

(open) position is advisable. The disconnect switch must

comply with NEC and local codes. Protect the unit and wiring

using only the recommended fuse/circuit breaker size (see

Tables 17 thru 20).

2. Run power wiring from electric panel to disconnect per

NEC and local codes.

3. Run power wiring from the disconnect switch to indoor and

outdoor units. Use only minimum 75

_

C copper conductors

between the disconnect switch and the unit for field power

connection.

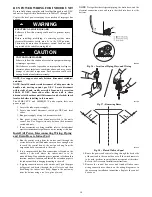

4. Route the field power wires through the conduit connection

opening in the unit side panel and connect in junction box

as shown in Fig 27 for outdoor units and the strain relief

bracket section for indoor units. The units and power wiring

must be grounded.

BLK

BLK

SINGLE-PHASE UNIT

GROUNDING LUG

SINGLE-PHASE

CONN TO

DISCONNECT

PER NEC

BLK

BLU

YEL

GROUNDING LUG

THREE-PHASE

CONN TO

DISCONNECT

PER NEC

THREE-PHASE UNIT

GROUND LEAD

GROUND LEAD

LEGEND

NEC -- National Electrical Code

-- Splice (field)

Field Wiring

Factory Wiring

A08251

Fig. 27 – Line Power Connections

NOTE

:

Operating unit on improper line voltage constitutes

abuse and may affect the manufacturer’s warranty. DO NOT

install unit in a system where voltage may fluctuate above or

below permissible limits.