10

3. Initial Unit Disassembly

S

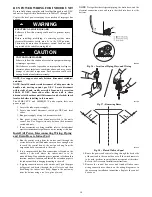

Remove the screws on the front of the unit to open the

grille.

S

After removing the grille, remove the screws in the side

panels.

S

Push the side panels in the direction shown in Fig. 16 to

disassemble them.

Remove the screws to open the grille.

Remove the grill.Then remove the screws of side panel.

Push the side panel as the arrow direction to disassamble them.

Fig. 16 – Initial Unit Disassembly

Ceiling Installation

1. Install Suspension Bolts for Ceiling Installation

S

Mark the spots on the ceiling where you want to install the

indoor unit.

S

Drill holes at the marking spots and then insert bolt anchors.

Use a hole--in--anchor, sunken insert for existing ceilings.

S

Install the suspension bolts (use W3/8 or M10 suspension

bolts, 4 pieces) depending on the ceiling type.

CAUTION

!

It is recommended to install the Y joint before installing the

indoor unit.

When moving the unit during or after unpacking, make sure to

lift by holding its hooks.

Do not exert any pressure on other parts, especially the

refrigerant piping and drain piping.

Suspension bolt (3/8” or M10) - field supplied

Hole in anchor

Hole in plug

Insert

A150268

Fig. 17 – Suspension Bolts

2. Hanging the Indoor Unit for Ceiling Installation

S

Screw double nuts to each suspension bolts making

space for hanging the indoor unit.

S

Hang the indoor unit to the suspension bolts between

two nuts (see Fig. 18).

S

Screw the nuts to suspend the unit.

S

Adjust level of the unit by using level vial for all sides.

CAUTION

!

Ensure that the ceiling is strong enough to bear the weight of

the unit.

Before hanging the unit, test the strength of each attached

suspension bolt. It might be necessary to reinforce the ceiling

frame.

Screw nut

Washer

Hanging

screw bolt

Overhang part

Shockproof cushion

A150269

Fig. 18 – Suspension Bolt Detail

3. Piping and Drainage Outlet for Ceiling Installation

S

The position of drain pipe interface can be selected

according to installation position. During adjustment of

the drain hose, the unused interface should be sealed

with a rubber plug.

20mm

Lean over 1% -2%

Drain hose

Refrigeration pipes

A150271

Fig. 19 – Drainage Outlet for Ceiling Installation

4. Install the Drain Pipe for Ceiling Installation

S

Remove the cover of the drain hose connection port

S

Insert the flexible hose onto the drain hose port. Securely

fix the flexible hose to the indoor unit with a pipe clamp.

S

Install the flexible hose onto the PVC water pipe (field

supplied, I.D. 1”) with PVC adhesive. See Fig. 20.

S

To ensure correct condensate water flow, the pipe should

have a gradient of 2% without obstruction (see Fig. 20).

DO NOT install the drainpipe to an upward position.

Doing so may cause water to flow back to the unit.