Chapter 4: Troubleshooting

4-6

EMM-E6 Installation Guide

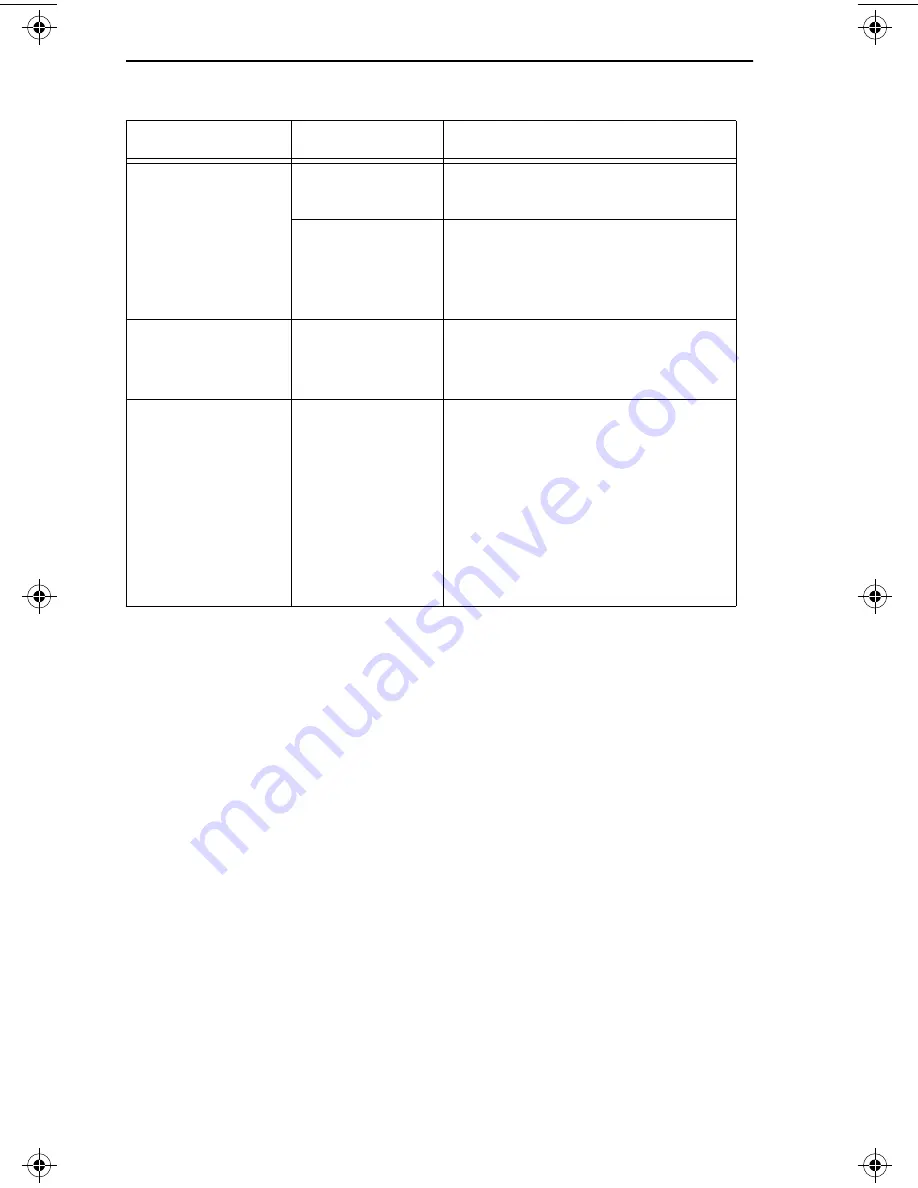

No power to an

external

transceiver

connected to an

EPIM-A.

AUI cable is

defective.

Replace AUI cable.

EPIM is

defective or

improperly

installed.

Replace EPIM. See Chapter 3,

Installation, for details.

High number of

collisions on EPIM

port.

External

transceiver has

SQE enabled.

Disable SQE.

Ports go into

standby for no

apparent reason.

Configurations

where devices

connected

across EMM-E6

channels can

cause the

EMM-E6 to

detect a looped

condition.

Discuss these configurations with

Cabletron Technical Support

before implementing them into

your network.

Table 4-2

Troubleshooting Checklist (Continued)

Condition

Possible Cause

Recommended Action

ICH1Book Page 6 Tuesday, August 6, 1996 3:06 PM

Summary of Contents for Spectrum EMM-E6

Page 1: ...EMM E6 ETHERNET BRIDGE MANAGEMENT MODULE INSTALLATION GUIDE D C B A E F ...

Page 2: ......

Page 20: ...Chapter 2 Controls and Indicators 2 8 EMM E6 Installation Guide ...

Page 48: ...Chapter 4 Troubleshooting 4 8 EMM E6 Installation Guide ...

Page 60: ...Appendix C Ethernet Cabling Requirements C 6 EMM E6 Installation Guide ...