9C300-1 Environmental Module Operation

3-4

System Humidity

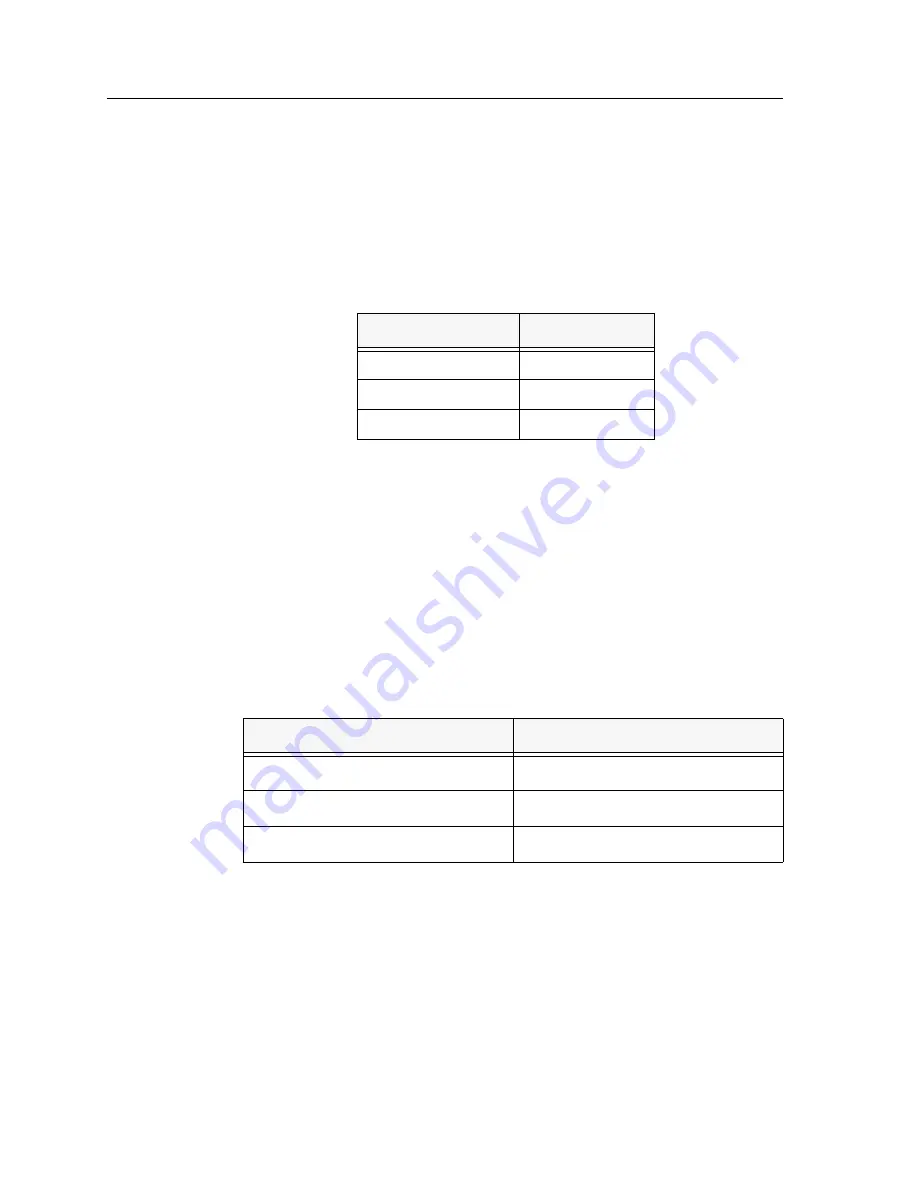

The 9C300-1 Environmental Module monitors the non-condensing humidity level

of the MMAC-Plus. The results of the monitoring are available to the network

manager via LCD, as well as local and remote management. The humidity levels

are displayed as shown in Table 3-2.

System Voltages

The 9C300-1 Environmental Module monitors specific system power parameters

to ensure that they are within acceptable limits. The power parameters monitored

from the backplane are the 48 volt DC System Power Bus and the INB

Termination Power Bus. The power parameter monitored within the

Environmental Module is the 12 volt internal line. The results of the monitoring

are available to the network manager via LCD, as well as local and remote

management. Voltages above or below the acceptable voltage limits cause an

alarm to be sent to the network manager. Table 3-3 summarizes these acceptable

voltage limits.

Internal Operating Temperature

The 9C300-1 Environmental Module monitors its own internal operating

temperature by comparing its current temperature to the ambient temperature

and programmed rise temperatures to determine current temperature status. If

the temperature of the Environmental Module exceeds normal operating limits,

an alarm is sent to the network manager. In addition, if the ambient temperature

sensor fails, pre-established temperature ranges have been programmed to ensure

proper internal temperature monitoring.

Table 3-2. System Humidity

Humidity

LCD Display

0–45%

STATIC RISK

46–94% NORM

(normal)

95% and above

MOIST

Table 3-3. Acceptable Voltage Limits

Description

Acceptable Voltage Limits

48 volt DC System Power Bus

From 40 volts to 59 volts

INB Termination Power Bus

From 3.1 volts to 5 volts

12 volt internal line

From 11 volts to 13 volts

Summary of Contents for Environmental Module TM 9C300-1

Page 1: ...MMAC Plus 9C300 1 Environmental Module User s Guide...

Page 2: ......

Page 36: ...9C300 1 Environmental Module Operation 3 24...

Page 46: ...EPIM Specifications A 8...