MACH4

Loading Material

Edition 7/06

Operator’s Manual

21

6.3.2

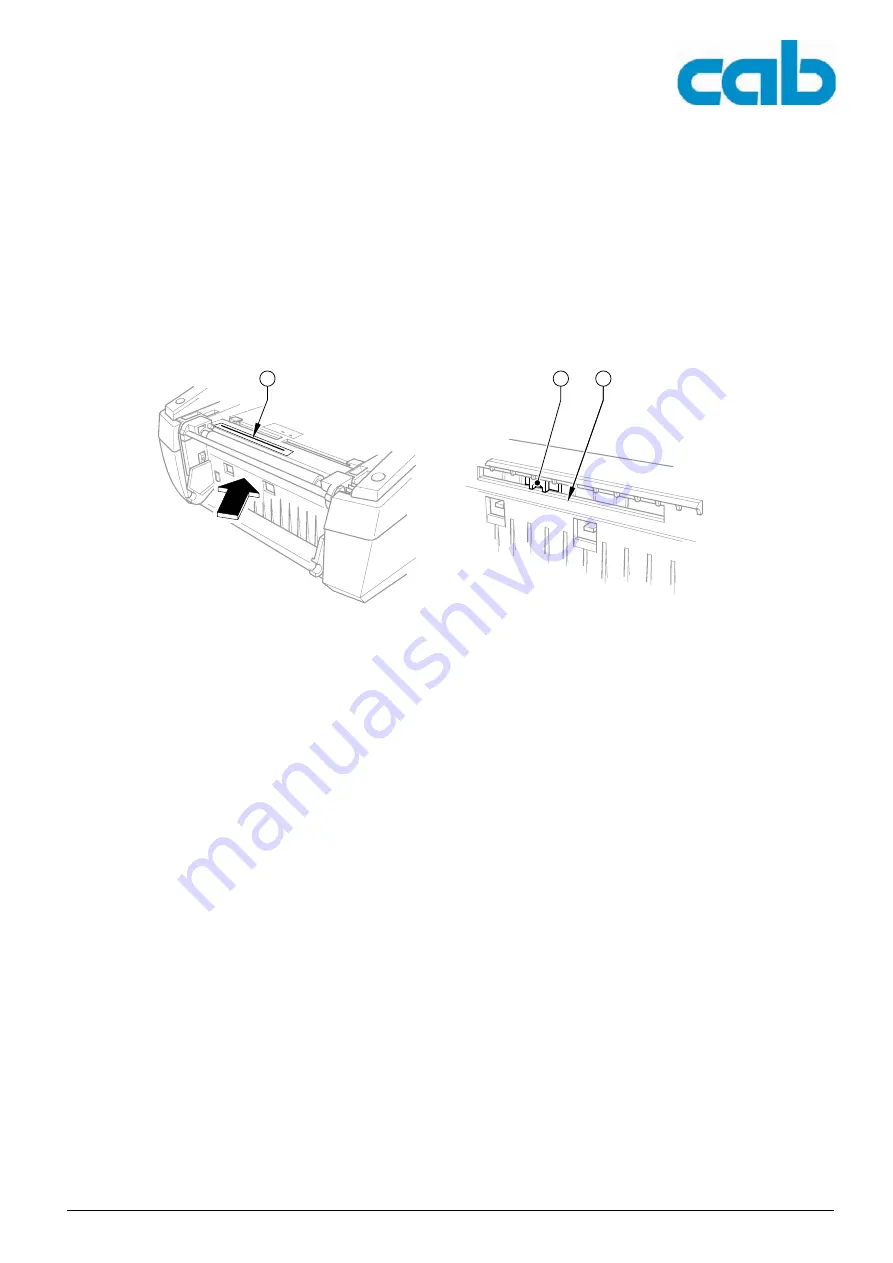

Reflex sensor

The reflective sensor (1) can detect marks on the back of the label stock. Move the sensor transversely

to the transport direction with the slide (2) to adapt to the position of the reflective marks:

⇒

Determine the distance of the reflective marks from the center of the material.

⇒

Move the slide (2) to the desired position with a pointed tool.

The distance of the sensor from the center is shown on the scale (3)..

Fig. 9:

Adjusting the Reflex Sensor

10

10

0

20

30

40

50

20

10

0

10

30

40

50

2

3

A

1

View A