CAUTION

During operation the surface of the vacuum pump may reach tem-

peratures of more than 100°C.

Risk of burns!

l

Make sure that the vacuum pump is shut down and cannot be ac-

cidentally switched on again

l

Let the vacuum pump cool down before starting any maintenance

work.

l

Prior to disconnecting pipework make sure that the connected pi-

pes/lines are vented to atmospheric pressure

Maintenance Schedule

NOTE

: The maintenance intervals depend very much on the individual

operating conditions. The intervals given below have to be considered

as starting values which should be shortened or extended as appro-

priate. Particularly heavy duty operation, such as high dust loads in the

environment or in the process gas, other contaminations or ingress of

process material, can make it necessary to shorten the maintenance

intervals significantly.

Every 6 Months:

l

Make sure that the vacuum pump is shut down and locked against

inadvertent start up

l

Check the suction lines for contamination or blockages.

l

Check the cooling coils and the fan cover regularly for dirt, clean

when neccessary.

A dirty fan cover or cooling coils prevent the proper intake of coo-

ling air which can lead to overheating of the vacuum pump.

l

The electrical connections must be checked by a specialist.

Every 100 - 500 Operating hours

l

Clean the inlet filter on the suction side at regular intervals. The

cleaning intervals depend on the quantity of dust contained in the

drawn air

u

If the filter is too dirty to be cleaned:

Remove the cover and replace the filter

Every 1000 Operating hours

l

Check the vanes, for the first time after 2000 operating hours (see

“Carbon vanes”)

Every 1000 - 2000 Operating hours

l

Replacing the outlet filter (SD version only). To do this, lift the co-

ver (see “Suction filter and outlet filter”)

The bearings are pre-lubricated for life and will thus not require

main-tenance. Replace by original roller bearings only

Inlet filter and pressure filter (SD)

The inlet filter and the pressure filter must be cleaned at regular inter-

vals, depending on the amount of dust in the air being pumped. Blow

out the filter cartridges with compressed air from the inside out. If the

cartridge is too dirty to be cleaned, it must be replaced.

The cartridges can be taken out after the removal of the filter cover.

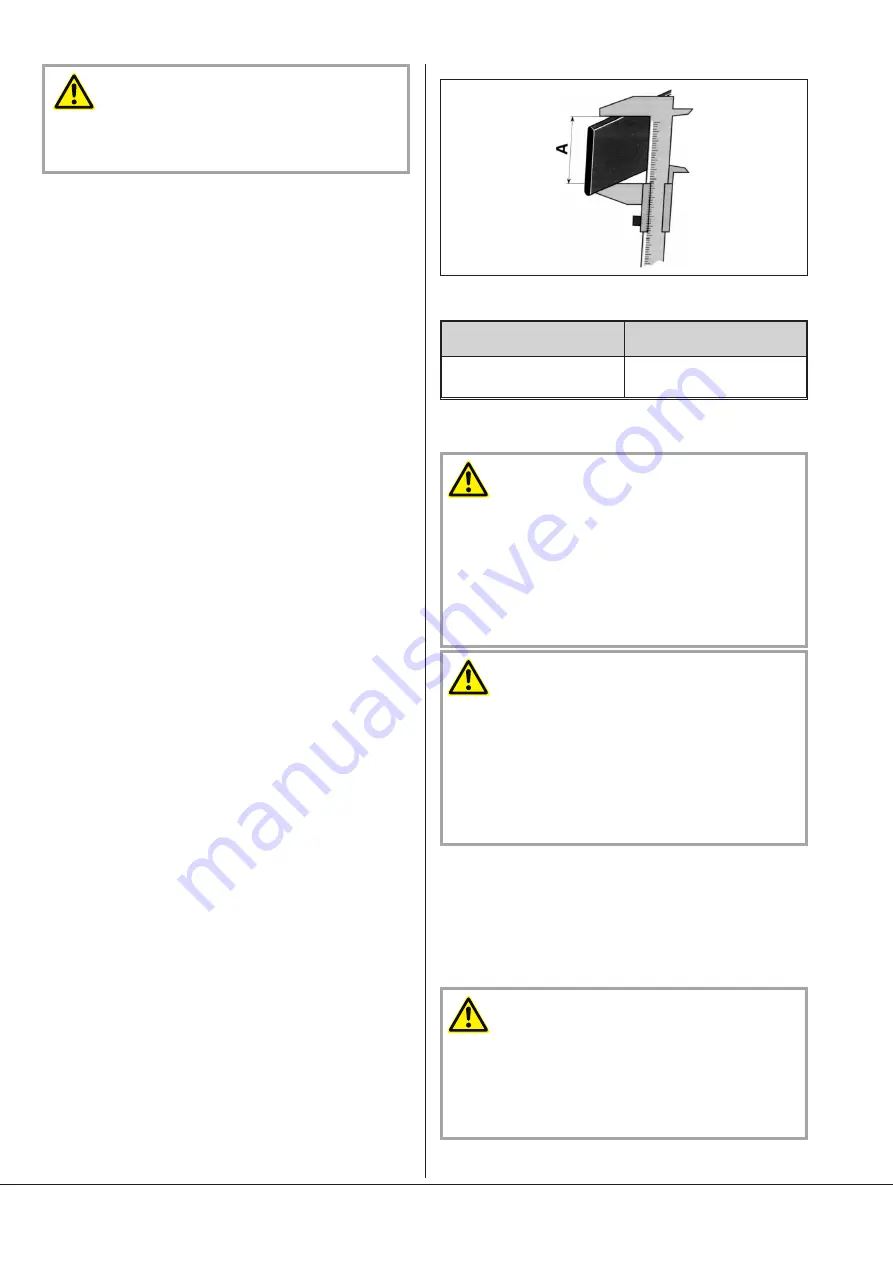

Vanes

The lifetime of the carbon vanes (

VA

) depends on the application of

the

vacuum pump. If the width of the vane reaches the given limit for

re-placement, it is necessary to change the vanes.

Remove the filter cover and the cylinder endplate to change the

vanes.

Blow out the compression chamber with dry compressed air.

Make sure that the vanes are positioned correctly and the right way

round (curved edge facing the cylinder wall).

Pump type

Width of vanes

minimum A

SV/ SD 1100 C

26 mm

Overhaul

CAUTION

In order to achieve best efficiency and a long life of operation, the

vacuum pump has been assembled and adjusted with specifically

defined tolerances.

This adjustment will be lost during dismantling of the vacuum

pump.

It is therefore strictly recommended that any dismantling of the va-

cuum pump that goes beyond of what is described in this manual

must be done by the Busch service.

CAUTION

Improper work on the vacuum pump will put the operating safety at

risk.

Risk of explosion!

Approval for operation of the vacuum pump will be void!

Any dismantling of the vacuum pump that goes beyond of what is

described in this manual must be done by specially trained Busch

service personnel only.

Removal from Service

Temporary Removal from Service

l

Prior to disconnecting pipes/lines, make sure that all pipes/lines are

vented to atmospheric pressure

Recommissioning

CAUTION

Vanes can stick after a long period of standstill.

Risk of vane breakage if the vacuum pump is started with the drive

motor.

After longer periods of standstill, the vacuum pump must be turned

by hand.

After longer periods of standstill:

Overhaul

Page 8

Summary of Contents for SECO DC 0063-0100 B/C

Page 13: ...Exploded view Exploded view Page 13 ...

Page 19: ...Note ...