5 | Installation

20 / 36

0870557375_NC2000B_VR_Ex_A0002_IM_en

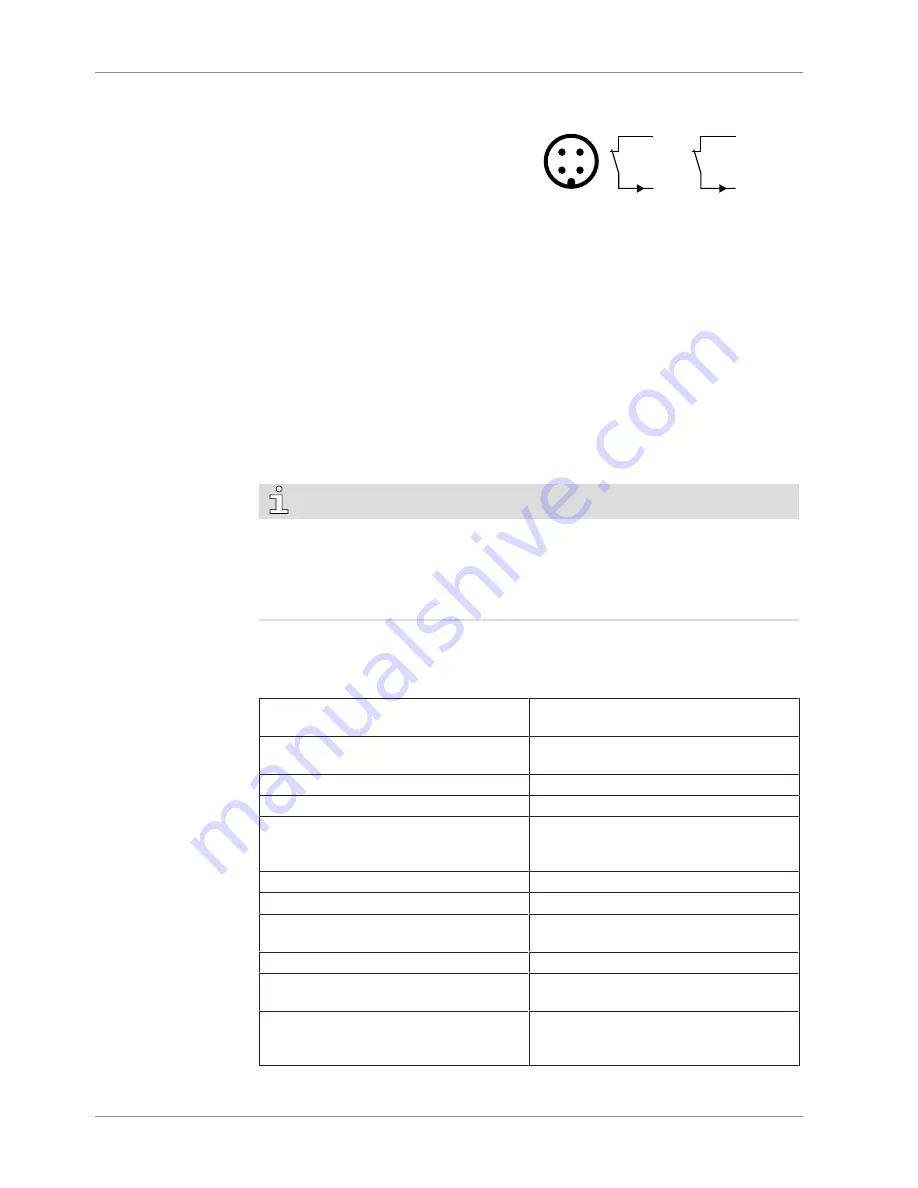

5.7.3 Wiring Diagram Level Switch

Part no.:

0652 556 531

Supplier reference:

Endress&Hauser FTL50/FEL58

Maintenance procedure:

Procedure F [

►

29]

Connector:

M12x1, 4-pin

P&ID position:

LS-/0201 & LS+/0202

Electrical data:

Ui = 16 VDC ; Ii = 52 mA ; Pi = 0.17 W ; Ci

= 0 nF

1

2

4

3

4 -

1 +

L

2 -

1 +

L

I

I

1 = Brown ; 4 = Black

1 = Brown ; 2 = White

Switching element function:

NAMUR

Contact:

Normally closed

Switch point:

L

trip

= LS-/0201

►

pin 1 + 4

►

low level “stop the machine”

L

trip

= LS+/0202

►

pin 1 + 2

►

high level “stop the machine”

I > 2.2 mA

►

Level: OK

I < 1 mA

►

Level: not OK

►

“stop the machine”

NOTE

Prior to starting the machine, both level switched (LSA-/0201 and LSA+/0202) must be

checked.

The maximum time between two level checks is 24 hours.

The level switch outputs (LSA-/0201 and LSA+/0202) are to be ignored during the cyc-

lic operation oft he machine.

5.8 Operating Parameters

• Make sure that the cooling liquid complies with the following requirements:

Continuous cooling liquid injection rate*

(INJ)

2 … 6.5 l/min

Minimum constant cooling liquid injection

rate (INJ)

2 l/min

Cooling liquid flow rate (CLI)

18 l/min

Ambient temperature range (standard)

-20 … 40 °C

Ambient temperature range (high tempera-

ture version, refer to pump nameplate)

Specific motors

-20 … 60 °C

Cooling liquid supply temperature

10 … 40 °C

Max. allowable gas inlet temperature

70 °C

Max. exhaust gas temperature (TSA

+/0102)

80 °C

Recommended exhaust gas temperature

60 °C

Max. cooling liquid outlet temperature

(TSA+/0101)

55 °C

Max. operational temperature difference

between cooling jacket and exhaust gas

outlet

70 °C

Summary of Contents for COBRA ATEX

Page 35: ...Note...