46

- Fixing the machine to a workbench.

The machine must be screwed to a workbench.

■

Mark the position of the mounting holes (A)

on the workbench.

■

Drill holes at each of the marked positions,

adjusting the diameter and depth of the holes to

the screws used.

■

Place the machine on the workbench and

insert the screws into the mounting holes.

■

Firmly tighten the screws.

- Information to set the minimum size of

the pieces to be cut

Minimal workpiece sizes (= all workpieces that

can be clamped left or right from the saw blade

with the provided quick-action clamp “E”

160 x 30 mm (length x width)

- Information on the maximum cross

section of a workpiece in a cross

Bevel

Miter angle

0°

45°

0°

208 mm

x 60 mm

208 mm

x 35 mm

45°

208 mm

x 35 mm

135 mm

x 35 mm

- The outer diameter ranges, the bore

diameter and the thickness of the

blades can be used

Blade Diameter

210mm

Bore diameter

25.4 mm

Blade thickness

2.8 mm

- The maximum depth of cut

Cutting capacity, max. (0°/0°): 208x60 mm

WARNING: Packaging

materials are not toys!

Children must not play with

plastic bags! Danger of

suffocation!

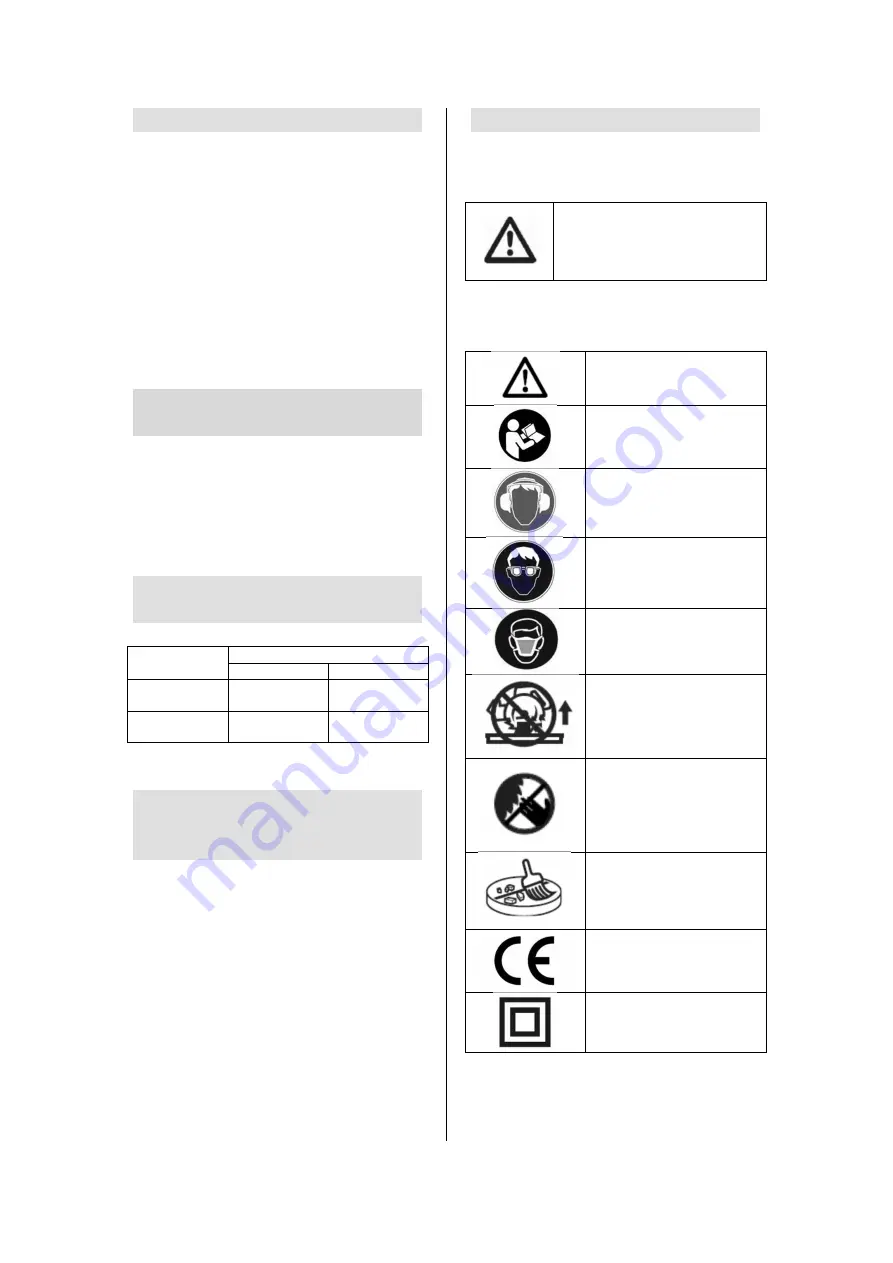

Symbols

Warning / Danger!

Read manual before use.

Wear ear protection.

Wear eye protection.

Always wear a dust

mask.

To avoid injuries caused by

projected keep the

machine head downwards

after cutting until the blade

is completely stopped.

Keep hands away from

the cutting area while the

machine is running.

Danger of injury when

coming in contact with the

saw blade.

For your safety, remove the

chips and other small

pieces on the table before

starting work.

In accordance with

essential applicable

safety standards of

European directives

Double insulated

Summary of Contents for 5411074157999

Page 2: ...2...

Page 3: ...3 Remplacement de la lame de scie Vervangen van de zaag Changing the saw blade...

Page 4: ...4 LASER...

Page 49: ...49...

Page 50: ...50...

Page 51: ...51...

Page 52: ...52...

Page 54: ...54...

Page 58: ...58...